Vapor Blasting 101

Free Download

The Dustless Blasting Equipment Catalog

Equipment, pricing, and the mobile blasting business opportunity.

GET THE CATALOG

What is vapor blasting?

Vapor blasting is a form of abrasive blasting that uses water mixed with an abrasive media such as glass beads, aluminum oxide, or crushed glass to clean and prepare surfaces. It is also known as wet blasting. Unlike traditional sandblasting that just uses compressed air, vapor blasting reduces dust with the addition of water and allows for working in residential areas, pristine locations or job sites with other workers and bystanders present.

Learn more about the benefits of a vapor blasting machine.

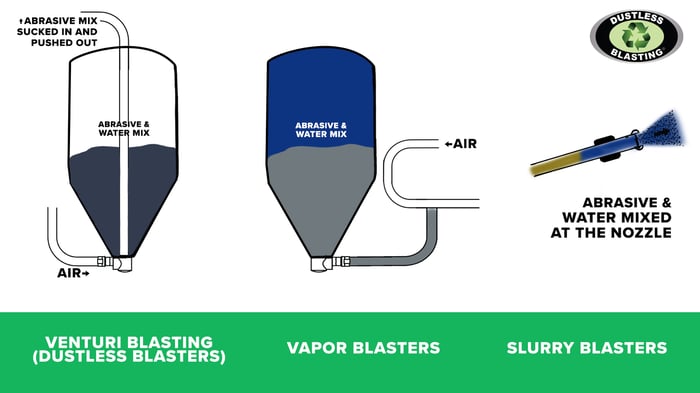

The Differences Between Vapor Blasting, Slurry Blasting and Venturi/Dustless Blasting

What differentiates these three blasting methods is where the water is added and how the abrasive + water mix is delivered from the pot, to the hose and out of the blast nozzle. Vapor blasters use water pressure within the pot to force the mix out and into the blast hose where it is then carried out to the nozzle by compressed air. This is different from our Dustless Blasting machines, also known as Venturi blasting equipment. This type of equipment forces a stream of high-pressure air through the pot, carrying the media and water mixture out of the blast pot and into the hose. Dustless Blasting machines reduce clogging because of this delivery method. Slurry blasting machines take traditional dry abrasive blasting technology and incorporate water at the nozzle for dust suppression. This method means the media isn't soaked in water inside of the pot and makes the blasting process less efficient.

Learn more about the differences between vapor, slurry and dustless blasting here.

Why Choose Vapor Blasting Equipment Over Dry Blasting

Worker Safety

Using wet blasting equipment has a significant advantage over traditional sandblasting as it reduces hazardous dust by 95%. The reason behind this is that water surrounds the abrasive particles, leading them to fall directly to the ground instead of remaining airborne. Therefore, vapor blasting is recommended by OSHA in situations where multiple people are present.

HEAT REDUCTION

Dry blasting causes significant heat generation on the substrate caused by friction which can cause problems. With wet blasting, water in the slurry mixture keeps the blasted surface cool, which helps to prevent thin metals from warping, weak substrates from cracking, and heat-reactive coatings from melting.

YOU'RE REMOVING EXTREMELY TOUGH COATINGS

At the same blast pressure, vapor blasting or wet blasting equipment will outperform dry blasting equipment due to their inclusion of water. Water not only helps to suppress dust and debris, but it also adds weight to the media, thereby enabling it to strike the substrate with greater force.

YOU NEED TO SIMULTANEOUSLY CLEAN THE SURFACE

Dry blasting can remove coatings, but it is not an effective cleaning solution. If you need to clean the surface, vapor blasting is a more efficient process that combines cleaning and coating removal.

Environmental Concerns

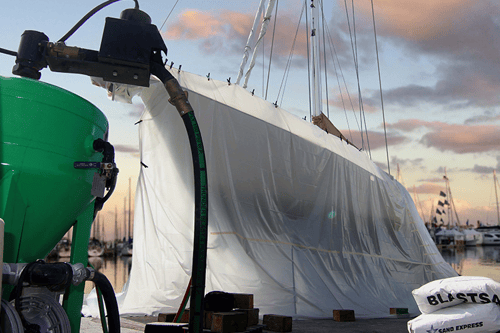

Wet blasting is a more eco-friendly option compared to sandblasting. This is because it can be easily confined and prevents airborne particles from harming natural areas and plants. Usually, marinas only permit the use of vapor blasting on dry docks to avoid spreading dust over water bodies. But with wet blasting, workers can easily control the project and keep debris at a safe distance.

For additional information on the benefits of vapor blasting, read this article.

VAPOR BLASTING VS DRY BLASTING VS SODA BLASTING

Each of these blasting techniques are useful in their own way depending on the job and what media needs to be used. If you're going to be a professional in the surface preparation industry, it's important to know when each method is appropriate.

Sandblasting

Sandblasting uses dry abrasive materials without including water in the blast pot or at the nozzle. This method is great for jobs that call for an organic abrasive like restoring log homes with corncob or walnut shells. It's also better to dry blast when the job has hard to reach places that can be difficult to clean wet media out of (for example: the inside of a vehicle or engine parts). However, dry blasting creates friction and heat that can lead to warping body panels or thin metal surfaces.

As previously mentioned, dry blasting is known for creating a hazardous plume of dust that can be very dangerous for operators and others nearby. If you're going to dry blast, make sure to wear respiratory protection.

VAPOR BLASTING

Vapor blasting should be used if warping is a concern because the water acts as a coolant and drastically reduces the heat. This is perfect for removing paint and rust from body panels or blasting softer metals. Wet blasting also is great for jobs in residential areas or if you're in need of a practically dust free process. Dustless Blasting systems consist of easy to use technology where operators can adjust pressure settings to blast a variety of surfaces. From cleaning delicate pool tiles with a round abrasive or removing powder coat while simultaneously creating a surface profile for paint to adhere to the surface.

Learn more about the specific benefits of vapor blasting in this related blog.

SODA BLASTING

Soda blasting is a blasting method that uses baking soda, or sodium bicarbonate to clean or leave a surface smooth. Soda blasting is great for cleaning, removing chemicals and fire restoration jobs. Each of these blasting methods have specific uses and applications.

Learn more about the differences between these blasting techniques here

VAPOR BLASTING EQUIPMENT

Many options exist for vapor blasting equipment so it's important to understand your needs and the services you wish to offer before purchasing a machine. Are you planning on blasting small parts at an existing business? Do you need to be mobile and take the machine with you? Let's discuss different types of machines to find the best equipment for your goals.

Portable Vapor Blasting Machines

The American made Dustless Blasting Equipment line is one of the best options on the market – giving you the versatility to switch between dry blasting, wet blasting, and soda blasting applications. Our venturi suction method allows you to store water and media within the pressurized blast pot without having to worry about clogging. You'll notice faster production rates with these machines due to the force of high-pressure air through the pot that carries the media and water mixture to the hose. The removal process is typically faster when your media is weighted down with water then it would be with dry air.

Blast Pots

Vapor blasting pots come in several sizes for a wide range of abrasive media capacity, materials, and runtimes to efficiently tackle both residential and industrial projects. Connect with an ADCS unit to dry blast.

Compressor-Ready Carts

Perfect for workshops, compressor-ready carts come with a blast pot and ADCS unit to seamlessly switch between wet and dry blasting all included on a forklift-compatible cart that can fit in most truck beds.

Mobile Blasting Trailers

A portable vapor blaster that comes with a blast pot, a powerful air compressor, a water tank, water pump and ADCS unit all mounted on a mobile trailer. This is the number one choice for contractors who need to offer vapor blasting services on a job site.

Learn more about how to get started with blasting by improving your existing business, tackling a specific project, or starting your own mobile Dustless Blasting business.

Vapor Blasting Cabinets

Unlike the portable Dustless Blaster, a vapor blasting cabinet is stationary and cannot be easily transported. This vapor blasting process is a good option for those at a shop who are cleaning small parts that can fit inside the machine.

Learn more about vapor honing technologies in this blog post.

Free Download

The Complete Dustless Blasting Catalog

Explore pricing, equipment, the industry, and everything you need to know.

GET THE CATALOG

VAPOR Blasting Media

Blast media or abrasive media are the particles that break away contaminants from the surface. Today, there are numerous abrasives to choose from depending on what you're blasting and how you want the surface to be left afterwards. You'll need to consider several things when choosing media.

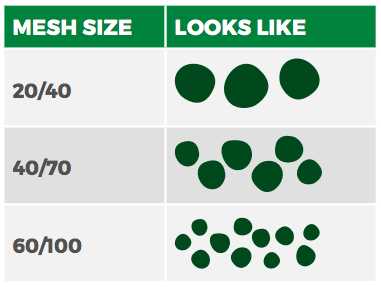

Size

Every abrasive comes in different sizes. Most abrasive is measured with mesh size. During production, it gets shaken through various screens. These screens might have as little as 20 holes per square inch, or as many as 100. This means that 40/70 glass fits through the 40–70 holes per square inch screens. 20/40 glass is coarser than 40/70, and 60/100 glass is finer.

Shape

Basically, there are two different shapes: angular which has sharp edges, and round with no edges. Angular abrasive has sharp edges which will cut into the substrate, leaving a surface profile for the new finish to stick to. Examples of angular shaped media would be crushed glass, slags and garnet abrasives to name a few. Round media is used mainly for cleaning or stripping while leaving the surface smooth. It will not rough up the surface or leave an anchor profile. Examples of round blasting media would be glass beads, sugar sand and plastic pellets.

Weight/Density

Understanding the weight or bulk density of the media you are using will also help decide which is best for the process. The heavier the media, the more impact it has on the surface you are blasting.

For wet blasting, you can use any abrasive media as long as it's clean, consistent and sinks in water. The most cost effective and popular choice media is 40/70 recycled bottle glass because it's environmentally friendly, chemically inert and contains less than 1% free silica. Other vapor blasting medias include:

- crushed glass

- garnet

- glass beads

- coal slag

- plastic

- aluminum oxide

- steel grit

VAPOR BLASTING APPLICATIONS AND USES

There are endless uses and applications that call for vapor blasting. Home owners, municipalities and local businesses everywhere need wet blasters who can remove paint, rust and contaminants from a variety of surfaces without creating the massive dust plume that dry blasting produces. Here are a few common industries and applications that call for wet blasting.

- Automotive/body panels

- Marine Maintenance

- Concrete

- Grafitti

- Metal surfaces

- Fiberglass

- Powder coating

- Bricks

- Stone

- Fire Hydrants

- Line stripe removal

- Remove paint, rust, epoxy, grease, bondo and sealer from a variety of surfaces.

Checkout this blog post to learn more about what you can vapor blast

BLOG ARTICLE

Vapor Blasting Applications

Learn more about what you can vapor blast.

READ THE ARTICLE

Safety tips for Abrasive Blasting

Consideration should aways be given to what type of coating is being removed, what type of abrasive is being used, and what environment you're blasting in. It can be dangerous to blast a soft surface with a harder abrasive.

Always practice safety precautions and containment for any blasting operation. This includes Personal Protection Equipment for all workers.

Keep these tips in mind:

- Always where the proper protective equipment. We recommend the RPB Nova 3 Blast Respirator.

- Use Containment - Read Containment and Cleanup Tips for ideas

- Be aware of OSHA guidelines related to abrasive blasting.

How do i contain and clean up after the job?

After vapor blasting, you'll have wet abrasive media and other contaminants to deal with. If you're able to setup some kind of containment before you blast, it will make the cleanup process much easier. Most blasters lay plastic underneath or around whatever they're blasting. Once the job is complete, they can roll it up and properly dispose of it. A power broom is a great tool to have if you aren't able to contain.

Next Steps

If you're ready to purchase a vapor blaster, checkout our products page or speak to a blasting expert.

Dustless Blasting also has an awesome business opportunity for those ready to control their future with versatile equipment. Download our catalog below for more information!

Free Download

The Complete Dustless Blasting Catalog

Explore pricing, equipment, the industry, and everything you need to know.