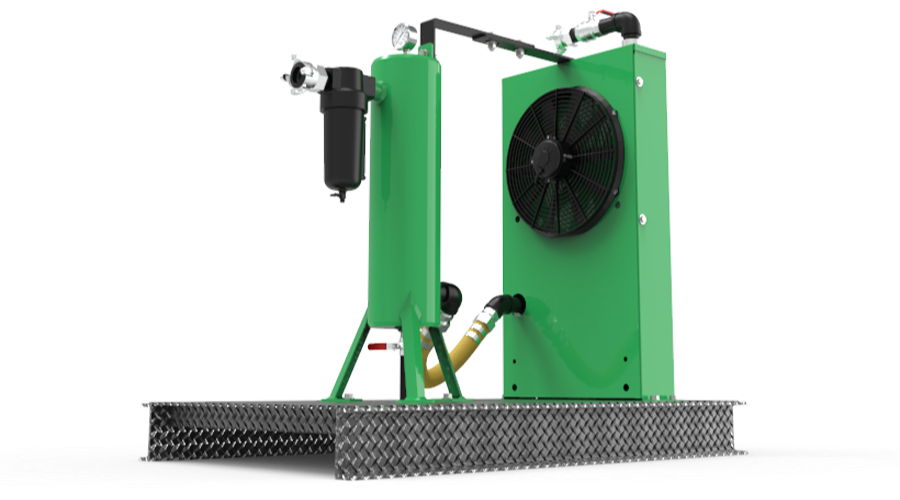

Portable Air Dryer & Compressor Aftercooler

Provides a cool, clean, and dry air supply up to 500 SCFM

Put a stop to clogging blast pots and poor blasting results.

Moisture is the enemy of efficiency when it comes to sandblasting, painting, and running pneumatic tools. Built in the USA to exacting standards, Dustless Blasting’s portable air dryer and compressor aftercooler is engineered for removing moisture from compressed air before it reaches your tools or sandblasting equipment.

When air is compressed and heated, water vapor condenses into liquid. This moisture can cause clogs and compromise paint texture. Our portable ADCS keeps your air supply cool, dry, and clean. Whether you’re working in a humid environment or need ultra-dry air for a flawless paint job, this compact unit ensures clean, dry air every time.

Features

Improves Job Quality

Ensures clean, bubble-free finishes during painting or powder coating

Decrease Operating Costs

Reduces downtime caused by clogged lines, wet abrasive, or tool malfunctions

Made in the USA

In our one and only Houston facility

- Cools, cleans, and dries air up to 500 SCFM at 150 PSI

- Air is oil and moisture free

- Cooling of source air within 15% ambient

- Powered by an AC to DC power supply provided or included 12 volt battery clamp

- Three ways to move: Swivel casters with wheel locks, Crane Lifting Ring, Spring Return Two Man Lifting Handles

Specifications

- Dimensions: 31" X 22" X 21"

- Weight: 127 lb

- Max Pressure: 150 PSI

- Max Flow: 425 SCFM

- General purpose filter, Air quality: Within ISO 8573-1, Class 6 and Class 7 (particulates)

- 416 Cubic inch moisture trap with service drain

- 1 ¼” NPT Connection for high Air Flow Equipment

- ¼” quick coupler for hand tools

- 2 lug connectors for intermediate sized tools and equipment

When To Use A Portable Air Dryer

- Sandblasting: Prevents clumping of abrasive media and flash rusting on metal surfaces. Especially critical when blasting steel, iron, or non-galvanized surfaces.

- Painting/Coating: Eliminates fisheyes, blisters, or adhesion failures caused by moisture in the air supply.

- Pneumatic Tools: Keeps tools running smoothly without the damaging effects of moisture or corrosion.

- Powder Coating: Ensures a smooth, even powder application by delivering clean, dry compressed air.

Industries Served

Surface Prep & Restoration

Automotive & Body Shops

Manufacturing & Fabrication

Construction

Shipyards & Marine

Oil & Gas

Food & Beverage

Benefits of ADCS Units

Dry air prevents flash rust during blasting and ensures clean, bubble-free finishes during painting or powder coating.

Dry air protects your parts, paint guns, and pneumatic tools from corrosion caused by trapped moisture.

Put money back in your pocket by increasing work efficiency, using less abrasive, and protecting against preventable damage to your blast pot.

Keep Moisture Out. Keep Performance In.

Combine your power

Rather see our products in person? We're happy to offer hands-on demos in Houston, TX.

Shop Other Products

ADCS-350

This skid-mounted air drying and cooling system is perfect when you need a stationary solution for in-shop projects.

Compressor Ready Carts

Looking for mobility in your shop? Our compressor-ready carts come equipped with an ADCS and one of our lifetime-warrantied blast pots.

Mobile Trailers

Mobile trailers offer a complete setup including an air compressor, water tank, ADCS unit, and blast pot, all mounted on a towable trailer.

Get Started Today!

Talk To an Expert

Do you need answers before taking the next step? One of our blasting experts would be happy to answer any questions you have about our products.

Upgrade Your Operations

Learn how you can save your business time and money by bringing all of your surface preparation needs in-house.