As operating costs continue to rise, major companies worldwide are more and more looking for quality solutions in every sector that get the job done faster, cost less to maintain, and increase worker safety. The surface preparation industry is no different.

Dry sandblasting and other traditional removal methods are often no longer sufficient for modern needs. And that's OK, because newer vapor blasting systems offer substantial advantages over these older technologies.

This blog post will first discuss the benefits of vapor blasting equipment and then explain how DUSTLESS BLASTING® goes a step further than other wet blasting equipment.

Benefits of Vapor Blasting Equipment

A Dust Free Process

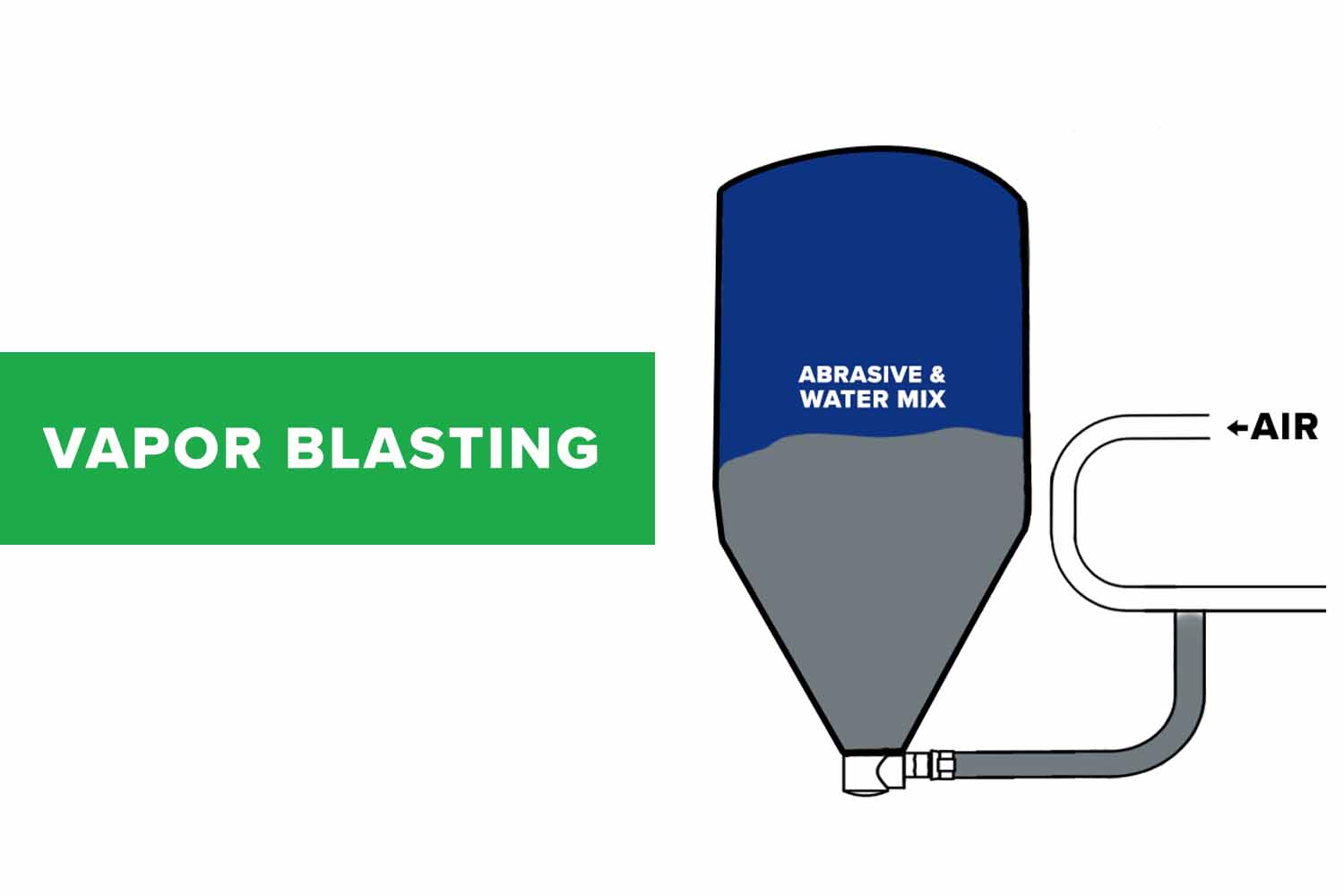

Commonly known as sandblasting, dry blasting can cause harmful debris to float freely, posing risks to the environment and the operator's health if inhaled. A vapor blaster, however, makes use of a slurry - combining water with abrasive media inside of the blast pot. This abrasive and water mixture adds extra weight to the blast debris, carrying it to the ground quickly after being blasted from the part surface.

Please note that the term "Dust Free" does not imply that the wet abrasive blasting process is entirely devoid of hazards or mess. Despite being considerably safer than dry sandblasting, wet blasting or vapor blasting still involves the forceful removal of paint and other industrial coatings, which may necessitate the use of personal protective equipment and debris containment as required by your local laws and regulations. Therefore, it is strongly advised that blasters and businesses should acquaint themselves with their local laws and regulations regarding PPE and containment requirements for wet sandblasting.

Vapor Blasting Equipment Increases Blasting Power

At the same blast pressure, vapor blasting or wet blasting equipment will outperform dry blasting equipment due to their inclusion of water. Water not only helps to suppress dust and debris, but it also adds weight to the abrasive material, thereby enabling it to strike the substrate with greater force.

Wet Blasting Saves You Money

In this business, abrasive media is a significant expense. However, by using wet blasting instead of dry blasting with the same blast pressure, less media is required to accomplish the same task, resulting in more efficiency and cost savings.

Wet Blasting Cools the Blasted Surface

Dry blasting causes significant heat generation on the substrate caused by friction which can cause problems. With wet blasting, water in the slurry mixture keeps the blasted surface cool, which helps to prevent thin metals from warping, weak substrates from cracking, and heat-reactive coatings from melting. This is especially important for automotive projects and powder coating removal.

Upgrade to Dustless Blasting Vapor Blasting Equipment

Let's talk about where Dustless Blasting has innovated beyond the typical vapor blasting system.

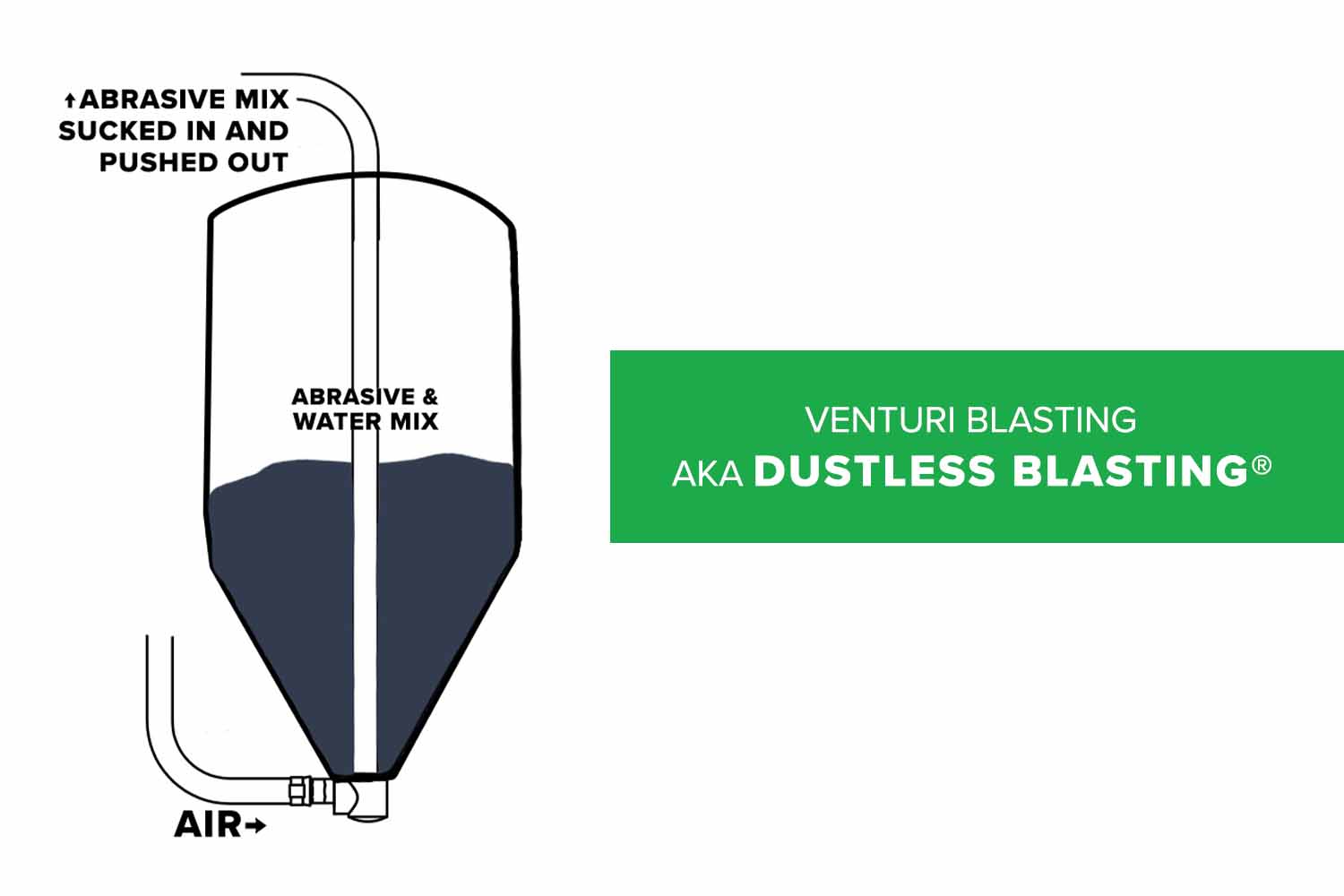

Our Venturi System Prevents Clogging

Unlike vapor blasting machines that rely on gravity to move media through the pot, Dustless Blasting takes advantage of the Venturi effect which creates a vacuum when air flows through a constricted section of pipe. This process is ideal to prevent clogging in the blast pot or other issues that you'll find with standard slurry blasting or wet blasting machines.

Learn more about the difference between slurry blasting, vapor blasting, and Dustless Blasting in this related blog.

Made in the USA and Backed with a Lifetime Warranty

Our Dustless Blasting blast pots are manufactured in the USA and are backed with a lifetime warranty, making it a smart long-term investment.

Blast with any abrasive

With Dustless Blasting equipment, you can wet blast, dry blast, or soda blast all with one machine. Switch between your method of choice in a matter of minutes.

Versatility

Our mobile trailers come with an ADCS (air drying and cooling system) that provides clean and dry compressed air. This allows workers to hook up various air tools, like a paint gun or air hammer, to provide additional services to their customers with the same tool.

WET BLASTING EQUIPMENT

Vapor blasting equipment is a perfect alternative to traditional dry blasting and provides greater blasting power, dust-free operation, increased media efficiency, and reduced operating costs.

For those looking for an even higher level of quality and performance, our Dustless Blasting equipment offers even more versatility and revenue potential than other vapor blasting systems on the market.