The Ultimate Guide to Soda Blasting: Everything You Need to Know

Free Download

The Dustless Blasting Equipment Catalog

Equipment, pricing, and the mobile blasting business opportunity.

GET THE CATALOG

Soda blasting is a trusted form of abrasive blasting that uses baking soda as its abrasive to clean, remove paint, and remove grease, leaving your surface clean and looking like new. Soda blasting is generally considered safer, non-toxic, and more environmentally-friendly than traditional methods like sandblasting, making it the perfect choice for cleaning sensitive surfaces or delicate substrates. In this guide, we will talk about what soda blasting is, applications and uses, soda blasting equipment, soda blasting media, the soda blasting process, and more. Let's get started!

What is Soda Blasting and How Does it Work?

Soda blasting is a form of dry abrasive blasting that uses sodium bicarbonate (also known as "soda" or "baking soda") as the abrasive media. The soda particles are forcibly propelled against a surface using compressed air.

Soda blasting is typically considered a milder form of abrasive blasting.

The Benefits of Soda Blasting

Baking soda is known to be a soft abrasive. It is typically harder than the surface contaminant (coating), but softer than the substrate (material being blasted). One of the most important differences between blasting with sodium bicarbonate (baking soda) - versus blasting with any other abrasive media - is that baking soda’s attributes allow it to remove contaminants without damaging the underlying substrate.

Soft abrasive blasting is excellent for cleaning materials which need to be reused, like food processing equipment, for example. Soda is also water soluble, so eliminating spent media after blasting is as easy as spraying down the equipment, making sure no abrasive remains in critical areas.

What Can I Soda Blast?

Soda Blasting Uses and Applications

If you need to clean or remove coatings efficiently and effectively on a delicate surface – soda blasting is the way to go. You'll most often see soda blasting in cleaning applications because it leaves a smooth surface without any rough texture or anchor profile.

There are quite a few uses for soda blasting. These include:

- Paint removal

- Protective coating removal

- Cleaning in food processing facilities

- Stripping and cleaning car frames and parts

- Graffiti removal

- Oil removal

- Maritime applications – boat hulls or boat hull cleaning

- Cleaning carbon, grease and grime from parts

- Historical restoration

- Cleaning masonry

- Wood restoration, stripping, and cleaning

- Line striping

- Fire restoration / soot remediation

- Mold removal and restoration

- Cleaning rolls in printing presses

- Gum removal

- Cleaning drilling heads, pipes and other equipment in the oil & gas industry

- Removing calcium deposits from metal

- Maintaining industrial equipment and heavy machinery

Soda may also be used in various types of blasting cabinets when blasting smaller items.

Check out our article "Uses for Soda Blasting" to learn more.

Soda Blasting Equipment

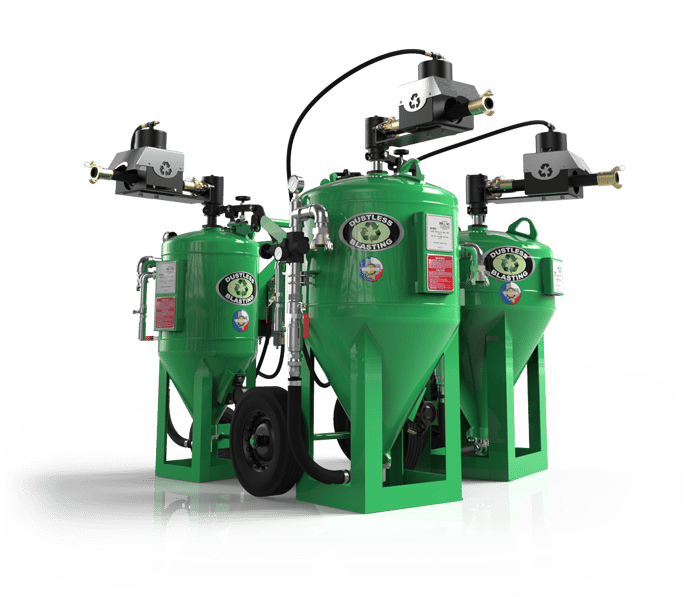

The American-made Dustless Blasting Equipment line is one of the best options on the market for soda blasting equipment. Because of the versatile technology, you can switch between dry blasting, wet blasting, and soda blasting applications as needed with the Dustless Blasting pot.

You typically need 5 things to get started with soda blasting.

- An air compressor that can generate the required CFM for your nozzle side and desired blast pressure.

- An Air Cooler and Moisture Separator to prevent the media from clogging or clumping.

- A blast pot, blast hose, and a blast nozzle.

- Sodium Bicarbonate, or other blast media.

- Personal Protective Equipment or "PPE".

The Dustless Blasting mobile trailers are an all-in-one system that you can use for soda blasting, wet blasting and dry blasting applications.

If you already own an air compressor, Dustless Blasting also carries standalone blast pots, Compressor-Ready Carts and Air Drying and Cooling Solutions.

Mobile Blasting Systems vs. Stationary Blast Cabinets

Blasting cabinets are typically designed to recycle abrasives. Unlike other forms of media, soda media is a single-pass media, meaning it cannot be recycled and used again.

In addition, the dust created during the blasting process greatly reduces visibility inside cabinet. However, there are blast cabinet systems specifically designed for blasting soda that address these issues. It's best to have a blast cabinet dedicated to soda basting instead of trying to retrofit a cabinet designed for recycling abrasive.

Click here to read our blog post on Soda Blast Equipment: Everything you Need to Start Blasting

Free Download

The Complete Dustless Blasting Catalog

Explore pricing, equipment, the industry, and everything you need to know.

GET THE CATALOG

Soda Blasting Media – Sodium Bicarbonate aka "Baking Soda"

When people talk about abrasive blasting, they often refer to it as "sandblasting" — a general term that doesn't reflect the wide variety of blasting media available today. In reality, there are many different types of media used in abrasive blasting, each with its own properties and ideal applications. These include materials like aluminum oxide, garnet, steel grit, plastic beads, and silicon carbide, among others.

Soda blasting is one such method. It uses sodium bicarbonate — commonly known as baking soda — as the blasting media. Unlike many other abrasives, sodium bicarbonate is a one-time-use media, meaning it cannot be recycled or reused after blasting. This is an important consideration when evaluating cost and media management.

What makes soda blasting unique is its gentle yet effective cleaning action. Sodium bicarbonate can remove contaminants such as grease, paint, mold, and corrosion without damaging the underlying surface. This makes it an ideal choice for delicate materials, soft metals, or projects where preserving the substrate is critical — such as in fire restoration, food processing equipment, or historical preservation.

Soda blasting offers a non-destructive alternative to traditional abrasives, making it a valuable tool for precision cleaning and surface preparation.

On the MOHS Scale of hardness (1-10), the sodium bicarbonate particles have an average rating of 2.4. This is less likely to leave a surface profile on the material being blasting and makes it a good choice for delicate substrates. In addition, soda will not leave particle residue embedded on the surface profile and is water soluble.

Soda blasting with sodium bicarbonate can act as a natural rust inhibitor and prevent flash rusting. It can actually leave a coating on the metal that will inhibit rust for a period of time which is certainly an added benefit.

Costs of Soda Blasting

Soda blasting can be more expensive than other blast media. When possible, the best practice is to use equipment that allows the use of a wide variety of abrasives and consider a more affordable abrasive like recycled crushed glass.

Blasting soda or sodium bicarbonate can be purchased from any vendor that sells other types of blasting material or blast media.

While all baking soda is chemically the same, grocery store baking soda is not recommended. Be sure to purchase blast media specifically formulated and manufactured for soda blasting applications from your local abrasive distributor.

Will soda blasting damage plants, grass, or other flora?

While soda is considered non-toxic and environmentally-friendly, you still need to exercise caution when blasting near plant life. It is recommended that containment be set up to prevent the blast media from contacting the plants.

BLOG ARTICLE

SODA AS A BLAST MEDIA

Learn more about using Sodium Bicarbonate for blasting applications.

READ THE ARTICLE

Safety Tips for Abrasive Blasting

Consideration should aways be given to what type of coating is being removed, what type of abrasive is being used, and what environment you are blasting in.

Always practice safety precautions and containment for any blasting operation. This includes complete Personal Protection Equipment for all workers during dry blast applications and eye, ear and hand protection for wet blasting.

Dustless Blasting machines are capable of both wet (dustless) and dry blasting applications, making it a very versatile tool.

While wet blasting is preferred for dust suppression, there are occasions where dry blasting (like soda blasting) is appropriate.

Keep these tips in mind:

- Always where the proper protective equipment. We recommend the RPB Nova 3 Blast Respirator.

- Use Containment - Read Containment and Cleanup Tips for ideas.

- Be aware of OSHA guidelines related to abrasive blasting.

Containment: How to Clean Up After Soda Blasting

Containment and cleanup are important parts of any soda blasting job, especially since sodium bicarbonate is a single-use media that breaks down easily but still requires proper handling. Here's a breakdown of what’s recommended:

Containment helps control overspray, protects the surrounding environment, and makes cleanup easier.

1. Use tarps or plastic sheeting: Enclose the blasting area with heavy-duty plastic sheeting or tarps to prevent soda media from drifting into unwanted areas.

2. Create a controlled work zone: For indoor jobs, use containment walls or negative air machines to keep dust from migrating. For outdoor jobs, barriers or windbreaks (like fencing with sheeting) can help.

3. Consider a blasting booth or tent:

If you're doing frequent or professional work, investing in a dedicated blasting enclosure helps improve safety and cleanup speed.

There are some tips and tricks like dropping 6 mil plastic sheet down in your blasting area. Afterwards, you can cut the sheet into sections, and roll them up for easy disposal. Also, if you don't want to haul away spent media and debris when the job is done, consider using a debris pickup service.

Soda Blasting FAQs

Do I need a special nozzle for soda blasting?

For any sand blasting equipment, nozzle selection is very important for getting optimal results. Make sure your air compressor can always provide the appropriate amount of air needed for the nozzle size and type you using. Inadequate air supply can greatly reduce performance and efficiency.

Click here to learn more about abrasive blasting nozzles.

I just have a small project. Who can I call to soda blast for me?

There are Dustless Blasting equipment owners across North America. Do a quick web search for "Dustless Blasting near me" to see who is available locally to take on your project.

Is soda blasting considered a non-destructive method?

Yes! Soda Blasting is considered a non-destructive method for many applications in cleaning, paint stripping, and equipment maintenance.

Is soda blasting bad for the environment?

Soda blasting is considered safe and non-hazardous, especially when comparing to alternatives like chemical solvents that can be caustic and harmful to your health.

Can soda blasting remove powder coating?

Using a stronger abrasive like recycled crushed glass via a wet blasthing method will be more efficient and yield better results.

Check out this video to watch powder coating removal with the Dustless Blasting system.

Is soda blasting just baking soda?

All baking soda is chemically the same, however, you should purchase soda specially manufactured for blasting applications.

What is better, soda blasting or sandblasting?

It really depends on the project, the environment, and other factors. Soda blasting and sandblasting can be used for a lot of the same applications and projects. Blast equipment that can provide you with a wide variety of blasting uses, abrasives, and applications to tackle any job (like the Dustless Blasting system) is probably your best option.

Click here to Read our blog post about Soda Blasting vs Sandblasting.

Can soda blasting remove rust?

Soda blasting is only useful for removing light surface rust. It will not bring the surface back to bare metal. Dustless Blasting with recycled crushed glass is a more efficient and effective method for rust removal.

Click here for the complete list of soda blasting FAQs.

The Dustless Blasting Business Opportunity

If you're ready for a change and want to control your future – Dustless Blasting is pioneering a brand new industry – mobile surface preparation and cleaning. With versatile equipment that is made to move, you can offer a wide variety of onsite services.

Here is what inspired us to create this exciting business opportunity:

- Revenue Potential: The mobile paint stripping and cleaning industry is valued at over $10 billion annually, with strong year-over-year growth.

- High Demand: Look around. Everything is painted, rusty, or dirty. The demand for this service is everywhere, but providers are few and far between.

- Low Overhead / Startup Costs: You can start a business for around $50,000!

- Quick Startup Time: You can be operational in days — not weeks or months.

- High Margins: Need we say more?

- Scalable Growth: It’s easy to scale your business by adding trailers and crew as you grow.

- Smart Risk: We give you the best of both worlds. Benefit from a community of business owners, marketing support, and a trusted brand to help you succeed — all without franchise fees.

Did we mention it's not a franchise?

You work hard for your money, so we believe you should keep all the profits.

- No ongoing fees

- No corporate limitations

- No territories

- Keep 100% of your profits

We believe in setting you up for success, so you can count on training, support, marketing materials, and advertising services.

Free Download

The Complete Dustless Blasting Catalog

Explore pricing, equipment, the industry, and everything you need to know.