What is media blasting?

Media blasting (otherwise known as abrasive blasting) is a process of cleaning and preparing surfaces for various refinishing, restoration or coating applications. It involves propelling abrasive materials at high speeds against a surface to remove contaminants such as paint, rust, grease, scale and other corrosion, accumulated deposits or coatings. Media blasting can also be used to shape and texture metal parts and even plastic parts in preparation for welding or bonding.

For all things on abrasive blasting and the equipment used for optimal results, view this complete media blasting guide!

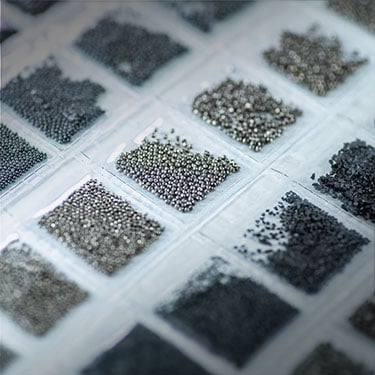

What are the different types of blast media?

While new products are always being developed and experimented on various applications, the most common conventional abrasives include:

-

Crushed glass

-

Glass bead (glass beads)

-

Steel shot

-

Steel grit

-

Aluminum oxide

-

Pyroxene

-

Garnet

-

Walnut shell (crushed walnut shells)

-

Corn cob

-

Coal slag

-

Plastic beads

-

Sodium bicarbonate

For a more comprehensive list of what is available on the market, including specs like density, Mohs scale rating and more, click here for our Guide to Sand Blast Media.

What is the difference between sandblasting and media blasting?

The term "sandblasting" was popularized when silica sand was the go-to choice for blast cleaning work. Nowadays, with what we know about silicosis, the substrate surface preparation industry has largely moved away from using silica sand as an abrasive choice. It's still common, however, to hear people refer to media blasting or dry blasting as "sandblasting".

Other terms often referred to within the blasting industry that all define the process of using an abrasive to remove surface contaminants include: glass bead blasting, bead blasting, soda blast or soda blasting, sand blasting, vapor blasting & more.

How much CFM do I need for media blasting?

CFM, or cubic feet per minute, refers to the amount of airflow that a compressor can supply within 60 seconds. The amount of blast pressure you need will vary depending on the size of your job, how quickly you need that work completed, and the demands of your other equipment, like your blast pot and nozzle. It isn't a simple question to answer, but generally speaking, you'll need a minimum of 60 CFM of compressed air for smaller, hobbyist projects and for serious industrial work, CFM requirements can be as high as 375+.

Dustless Blasting manufactures blast pots that can be paired with compressors starting at 60 CFM. To check out the requirements of the Dustless Blasting equipment, click here. Don't want to worry about sourcing your own compressor? Check out our all-inclusive mobile trailers here.

What are the differences between blast media types?

Some types of materials are better suited for different media blasting applications — for instance, softer abrasives like corn cob are great for blasting delicate surfaces like wood. Similarly, glass bead blasting is known for its gentleness, leaving surfaces smooth and more uniform and giving metal and steel a smooth satin finish.

On the more aggressive side, there are several types of abrasives that can get even the toughest jobs done. For example, steel shot, steel grit and pyroxene are better suited to blast tough coatings like paint and rust and have the ability to create a deeper anchor profile after stripping.

Which is the best abrasive for media blasting?

This is a trick question, as media blasting is not a one-size-fits-all process. The power in choosing a blast media lies within the research. So keep reading!

It is important to note that blast pressure and standoff distance play a significant role in the effectiveness of the blasting process, so it is always recommended to do a test area of the surface you are planning to blast. Another factor that contributes to selecting the right media is the level of surface preparation standard required. The SSPC, the NACE and the SIS have established four degrees of blast surface cleanliness. Understanding these standards will help you provide the best surface prep for your customers, and keep your costs down where possible. The types of surface prep are as follows:

-

White Metal Blast (Bare Metal Blast)

-

Near White Metal Blast

-

Commercial Blast

-

Brush-Off Blast

To read more about the types of blast surface cleanliness, search the Dustless Blasting Academy here.

How do you select ABRASIVE blasting media?

What is the process behind selecting the best abrasive for your media blasting job? Here's the answer straight from an existing media blasting business:

"What we do now is we start out with a very fine media if it's something that can be damaged... And if we find the fine media is not cutting fast enough, we’re always in a position to where we carry a lot of different medias so we'll step it up to a medium or an aggressive."

- Patrick, Dustless Blasting Business Owner

Again, the type of contaminant (rust, paint, epoxy, dirt/grime, etc.) and the substrate or material (metal, steel, wood, concrete, etc.) you are blasting all play a role in which media is ideal for the work. So does your budget! Learn everything you need to know about your abrasive options in our Complete Guide to Choosing The Right Abrasive.

Learn everything you need to know about your abrasive blasting media options in our Complete Guide to Choosing The Right Abrasive Blasting Media.

Where can I buy abrasive blast media?

Each category of abrasive has multiple manufacturers and distributors, so if you are struggling to find a particular type near you, check out our article here on Where Do I Buy Abrasive Blast Media?.

How many times can you reuse blast media?

The number of times you can reclaim and reuse spent media depends on the type of materials and what you've been blasting. Some types of sandblasting materials, such as aluminum oxide, silicon carbide and pyroxene can be reused many times before needing to be replaced. Other medias, such as copper or nickel slag, break down too quickly to for reclaiming to be worth the extra effort. Then there are options like soda blasting media, which cannot be reclaimed at all.

"Reclaiming glass bead (or glass beads) depends on the pressure and how clean the parts are that are being blasted. I strictly use glass beads in my [suction] blast cabinets in my garage, and I can use it for a bit by using a screen before needing to change it out. It is also 4x the cost of crushed glass in my area, so that is something to consider when reclaiming as well."

- Justin S. in Private Business Owner Facebook Group

Even if you can reuse blast media, it doesn't mean you always should. The characteristics of your abrasive (mesh size, shape, and hardness) may change from one use to another. For instance, if you're using an angular abrasive like crushed glass to cut through a tough coating (powder coating, for example) and profile the substrate, upon reclaiming that same media, you may not find it to be as effective as the first time you used it as the grit sizes can change.

"I tried reusing some blasted 40/70 crushed glass once when I ran out and needed one more pot to finish job. It worked but the grit size was changed from medium to fine, since the glass breaks down on impact and reduces in size."

- Janis Y. in Private Business Owner Facebook Group

production rate ⌛ can be more important than media savings

Time is money. And time spent cleaning and reclaiming your media might be better spent by continuing to blast with fresh media.

"Sometimes production rate overrules media savings. Some jobs we crank it open and let it rip. If we can cut the time in half... then we can move on to the next job and double the profit."

-Shawn C. in Private Business Owner Facebook Group

What's the Difference Between Media Blasting and Soda Blasting?

Soda blasting, also known as sodium bicarbonate (baking soda) blasting, is a type of media blasting process that uses baking soda particles to clean surfaces. The baking soda will help to clean underneath the coatings as it takes away the unwanted top layers of contaminants. In addition, sodium bicarbonate has a relatively low Mohs hardness of 2.5 which means it is one of the gentler abrasives out there.

A popular application for soda blasting is for fire remediation, because it cleans and deodorizes at once to get rid of that smokey smell. Another popular application for this type of blasting is removing calcium deposits from pools with a specialized soda made for this particular purpose.

While soda blasting is great for this particular product surface, it may not be the most environmentally friendly option for outdoor blasting as it can have a negative affect on vegetation. Be sure to do your research before soda blasting outside to see if there is another good alternative material for your project.

Learn everything you need to know about the soda blasting process with our Ultimate Guide to Soda Blasting.

How much should you charge for media blasting?

The cost of media blasting or "sandblasting" depends largely on the substrate being blasted, the total surface area that needs blasting, the quality of said blast, and the expected turnaround time. Some sandblasters will charge an hourly rate depending on the complexity of a job, while others may charge a fixed amount per square or linear feet.

How much does blast media cost?

As a surface preparation professional, the cost of abrasive media varies depending on where you are in the country, what is the media of choice and how much you are buying at a time. As a baseline, the general recommendation for many wet blasting projects is the use of a recycled crushed glass. This product is offered by a number of manufacturers but can typically be found between $11-13 per 50 lb. bag.

To learn more about where to source your blast media, check out this blog.

Why is Dustless Blasting the best choice for media blasting?

Simply put, Dustless Blasting is an incredibly versatile and capable media blasting tool with many benefits compared to traditional sandblasters or other surface preparation methods, the most noteworthy being the fact that our technology helps suppress dust.

-

With just one machine, blast with a variety of abrasive media including soda and organics (corn cob, crushed walnut shells, etc.) to remove coatings.

-

Switch between dry and wet blasting depending on your needs.

-

Tackle a wide range of jobs with our adjustable blast pressure regulator and media flow valve, from tough coating removal (higher pressure) to gentle cleaning and polishing.

-

Choose equipment from our strategically designed product line to fit your personal or business goals based on size, budget, run time, functionality.

From individual blast pots to all-in-one mobile systems, we've got a wide range of products designed for stripping and cleaning so your surfaces can take on a brand new form.

What can the Dustless Blasting machine blast?

You name it, Dustless Blasting can probably blast it! Below is a list of various surfaces that have been blasted successfully using our equipment when paired with the job-appropriate blast media:

-

Metal

-

Stainless steel

-

Aluminum

-

Plastic

-

Concrete

-

Stone

-

Fiberglass

-

Wood