With so many different types of media on the market for sandblasting, it can be hard to know what abrasive will be right for the equipment and job. Whether you're planning on removing paint, surface contaminates from metal surfaces, or specialize in rust removal, selecting the appropriate abrasive is important to maintain efficiency, conserve media, and protect any surface you're blasting. In this blog, we'll go over commonly used abrasive materials and what they're used for.

Differences in Sand Blast Media

Generally, there are two categories we can break abrasive media into. There are abrasives specifically for dry-media blasting, and there are abrasives that can be used in both wet and dry blasting. Dry blasting-specific media can't be used in wet blasting applications as the material does not sink in water, a key parameter for successful wet blasting.

Let's look at some examples.

The below charts show a few types of abrasive used in dry media blasting. Each abrasive has a listed hardness value, surface profile, surface removal ability, and velocity (if the blasting media travels at a high speed or a low speed from the blast pot's compressed air). Each of these characteristics are important when considering the best media for the job.

Dry Blasting Abrasive

Sugar Sand

Sugar sand is a round media used for light duty dry blasting, cleaning and stripping coatings – particularly when a smooth finish and minimal damage to the substrate are desired. Its fine-grit, white silica composition produces superior results compared to using other angular particles; but at comparable cost levels as glass beads, it's a great option for surface preparation projects!

|

Bulk Density

|

Hardness | Surface Profile | Surface Removal | Velocity | |

| Sugar Sand | 100 lb/ft3 | 6-7 |

High etch

|

Yes | Medium fast |

Corn Cob

Corn cob is made from crushing the woody ring of a corn cob into multiple sizes. It is an organic, soft media ideal for delicate surfaces like wood.

|

Bulk Density |

Hardness | Surface Profile | Surface Removal | Velocity | |

| Corn Cob | 40 lb/ft3 | 4-4.5 | No etch | No | Slow |

Walnut Shells

Walnut shells are organic angular abrasives for mildly powerful stripping without damage to the blasted surface. This blast media is beneficial for cleaning dirt, grease, oil, carbon and paint without changing the underlying substrate.

|

Bulk Density |

Hardness | Surface Profile | Surface Removal | Velocity | |

| Walnut Shell | 50 lb/ft3 |

4.5-5

|

Low etch | Very slight | Medium slow |

Sodium Bicarbonate

Sodium bicarbonate is a mild abrasive that won't damage delicate substrates. With its MOHS Scale of hardness rating at 2.5, it will not leave an unwanted surface profile on the material you're blasting-- leaving your substrate looking pristine and smooth with no embedded residue! Soda blasting is great for cleaning and fire restoration jobs as sodium bicarbonate effectively deodorizes that burned smell which lingers long after the fire has been extinguished.

|

Bulk Density

|

Hardness | Surface Profile | Surface Removal | Velocity | |

| Sodium Bicarbonate | 61 lb/ft3 | 2.5 | No etch | No | Slow |

While the abrasive material in the examples above can only be used in dry blasting, the below media can be used in either wet or dry applications. Remember, an abrasive can only be used to wet blast if the material sinks in water.

Wet or Dry Blasting Abrasives

Steel Grit

Steel grit is an angular abrasive used for fast stripping and aggressive cleaning. This blast media is a great option for cleaning metal surfaces that are covered in dirty, rust, mill scale, or paint.

| Bulk Density | Hardness | Surface Profile | Surface Removal | Velocity | |

| Steel Grit | 260 lb/ft3 |

40-65 HRC

|

High etch

|

Moderate | Medium fast |

Steel Shot

Steel shot blast media is wildly used for cleaning, polishing, peening and descaling. This abrasive is in a spherical shape which creates a smooth texture on the substrate surface.

| Bulk Density | Hardness | Surface Profile | Surface Removal | Velocity | |

| Steel Shot | 230 lb/ft3 |

40-51 HRC

|

No etch | No | Medium |

Aluminum Oxide

Aluminum oxide is a sharp, long-lasting media for fast glass etching and profiling. This blast media is ideal for industrial operations, such as cleaning turbine blades and engine parts. Its quick cutting action makes it an efficient solution for difficult to remove debris on metal surfaces and is used in anti-skid applications.

| Bulk Density | Hardness | Surface Profile | Surface Removal | Velocity | |

| Aluminum Oxide | 110 lb/ft3 |

8-9

|

High etch | Yes | Fast |

Glass Beads

Glass beads are used for general cleaning, peening and cosmetic finishing of sensitive surfaces; brightening grout and removing calcium deposits from tile; polishing cast iron, stainless steel, aluminum, propellers and turbine blades. Round, soda-like glass beads produces a bright, satin finish.

| Bulk Density | Hardness | Surface Profile | Surface Removal | Velocity | |

| Glass Beads | 95 lb/ft3 | 5-6 | No etch | Slight | Medium fast |

Crushed Glass

Crushed glass blast media is free from crystalline silica and made from 100% recycled glass. This is an efficient abrasive that has an angular profile which is great for removing a wide variety of coatings on many different surfaces. It produces a cleaner finish than most slags and is very cost conscious.

| Bulk Density | Hardness | Surface Profile | Surface Removal | Velocity | |

| Crushed Glass | 100 lb/ft3 | 5-6 | Medium-high etch | Slight | Fast |

Garnet

Garnet is an angular, hard media commonly used in place of silica sand. This fast-cutting abrasive works great for removing tough coatings, paint, rust and mill scale from steel.

| Bulk Density | Hardness | Surface Profile | Surface Removal | Velocity | |

| Garnet | 85 lb/ft3 | 7.5-8.5 | Very-high etch | Yes | Very fast |

Coal Slag

Coal slag is an angular blast media that is a byproduct of coal. This abrasive is used to remove coatings like rust and paint from steel and concrete.

| Bulk Density | Hardness | Surface Profile | Surface Removal | Velocity | |

| Coal Slag | 85 lb/ft3 | 6-7 | High etch | Yes | Medium fast |

Plastic Abrasives

Plastic is a soft media for many types of automotive and aerospace applications as it can remove paint and mold from delicate surfaces without causing damage. It is the preferred method compared to chemical stripping due to it being less hazardous.

| Bulk Density | Hardness | Surface Profile | Surface Removal | Velocity | |

| Plastic Abrasives | 50 lb/ft3 | 3-4 | No etch | Slight | Medium |

Now that we know a few examples of blasting media type, let's talk about other important characteristics to consider when selecting sandblasting media.

Abrasive Shape

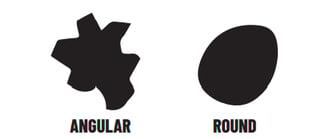

There are two main types of abrasive shapes - angular and round.

Angular media has irregular edges that create a textured surface in the blasted substrate. A textured or anchored surface is ideal for paint or finishes. Round-shape abrasive has smooth edges and will not leave a rough texture on the blasted surface. When the goal of blasting is to polish a surface without needing to create texture, a smooth shape will give the desired profile. See the picture below for a visual representation of the media shapes.

Abrasive size, density, and hardness

Looking back to the tables above, we can see there are more important characteristics than just the abrasive's shape. You should also consider the size, density, and hardness of your media.

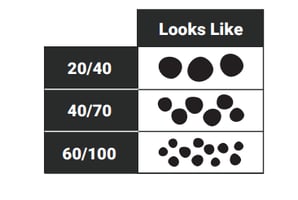

When it comes to size, most abrasives, or media, are measured by their mesh size. An abrasive’s mesh size is defined by the number of holes in a screen the media can pass through per square inch. Refer to the figure below for a visual representation of common mesh sizes.

With density, knowing the weight or bulk density of an abrasive media can help an operator choose the appropriate abrasive for the job. Blast media can have a high density or a low density measurement. The density is measured in pounds per cubic foot, so an abrasive with a bulk density of 75 lb/ft3 is less dense than a sample of 145 lb/ft3. The higher the bulk density, the more impact the abrasive will have on the blasted surface.

Lastly, you should consider an abrasive's hardness. Generally, a harder abrasive will impact the blasted surface profile more than a softer abrasive. A softer media, such as organic materials and plastics, is sufficient for removing dirt, oil, grease, and paint without damaging the target surface. An abrasive’s hardness may be measured in a couple ways. A common quantitative figure comes from the Mohs hardness scale. The media will fall on a scale of 1-10. 1 being the softest media and 10 being the hardest.

Keep in mind, choosing the harshest or coarsest sandblasting abrasive will not always yield the fastest or most efficient results. You should take into account all factors, such as wet or dry blasting, size, shape, density, hardness, and fragility of the blasted surface. If you're looking for a versatile, cost effective abrasive to get started on various applications, we suggest checking out our collection of 40/70 crushed glass.

Media Blasters

Professionals in the surface preparation industry must be able to utilize various abrasive materials for each job. However, not all blasting systems are created equal and some may limit which media is used due to their delivery methods. This is why Dustless Blasting equipment has revolutionized this space; with one system equipped to wet blast, dry blast or soda blast any surface, operators can navigate virtually every task without limitation!

With the right blasting equipment and appropriate sand blast media, your surfaces will be looking brand new in no time. For more information on media blasting, check out our media blasting page!