Choosing the Right Abrasive Blasting Media

When you are Dustless Blasting, it is vital to understand your abrasive blasting media options that go into achieving your desired surface preparation result. Whether you're wet or dry blasting, you'll need to choose the best abrasive for your needs in order to boost productivity and lower operating expenses.

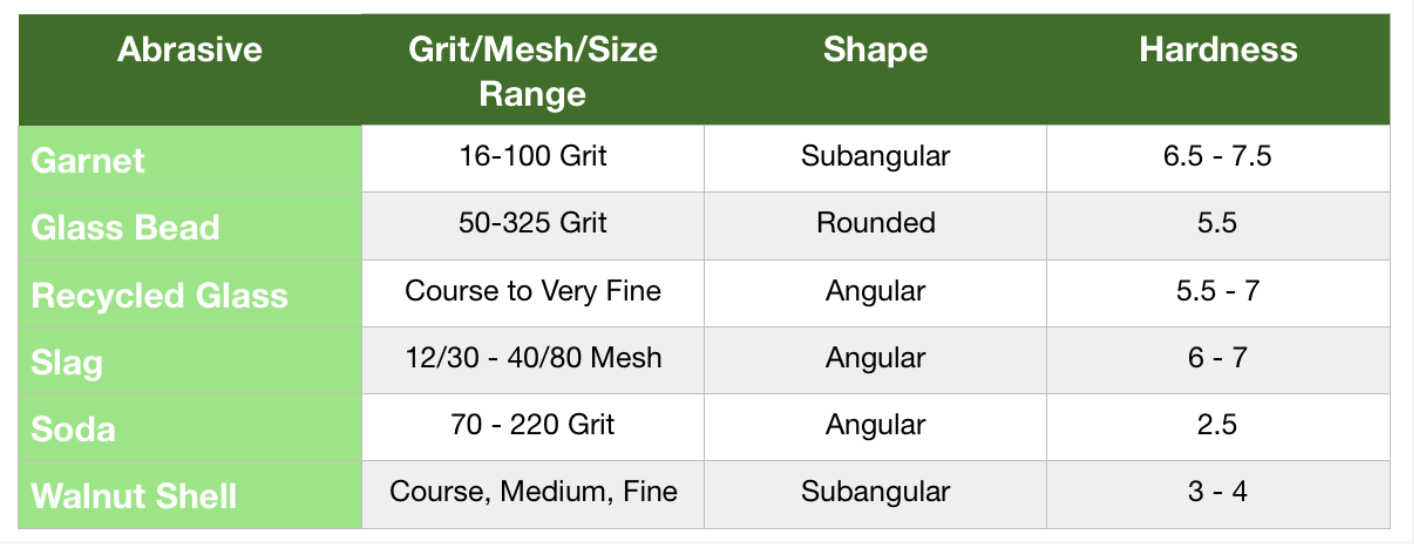

Blasting Media Characteristics

Different abrasives have different characteristics that influence how they blast through a coating or substance. Here is a quick look at the variance between the more popular blast media.

Size - This will impact coverage and cleaning speed

Shape - The sharpness of corners and edges influences how far you go with surface treatment

Hardness - The harder the abrasive, the more aggressive it can be.

Our Pick

Our top pick for abrasive is recycled bottle glass. We enjoy it because it is clean, cost-effective, eco-friendly, and suitable for a wide range of tasks. Glass-like sharpness and glass-like smoothness distinguish this media. It has a very sharp, glassy edge that may be used to cut into surfaces more quickly than sand, but it is less likely to cause harm because it is smooth. Visit our online store for recycled bottle glass media options for your abrasive blasting needs! You need to be sure that your abrasive is top quality with minimal trash and has particle sizes that are consistent.

You may think that blasting a wall with no preparation is easy, but it isn't. The right abrasive and changing your blast pressure and angles will allow you to efficiently remove surface coatings from your project.

Other Blasting Media Notes to Consider in 2022

Keep in mind that abrasives with sharper edges can more readily cut into your chosen surface. So the job can be done faster depending on the application. A soft media on the other hand can not blast as deeply into the surface, so you may not be able to get the adequate clean you are looking for. Any media that is rounded, warped, or bent can lead to irregularities while blasting. The blast media may not put enough material in some places while blasting too much in other areas.

Remember though, sand as a blasting media is rarely used due to the health and environmental hazards it can cause. Luckily, this is not something you will need to be concerned about because there are so many other and better methods for your abrasive blasting wants and needs. And no need to worry, these choices are just as great at getting rid of those surface coatings you've been having trouble with. Rust, metals, stainless steel, and other finishes won't get in your way anymore.

Abrasive Blasting Media Types

Steel Shot

Steel shot is an abrasive media that consists of small steel balls (typically 1/16 square inch or smaller). It is commonly used for grinding and polishing metal surfaces and paint removal.

Steel Grit

Steel grit is another option for the steel abrasives side, in addition to steel shot, which consists of small steel particles (typically 1/16 square inch or smaller). It's commonly used for grinding and polishing metal surfaces.

Power Sand

Power sand is an abrasive media that is very similar to steel shot; however, it has a softer composition which makes it safer to use on certain materials. Commonly used for paint removal, grout removal, and tile preparation.

Acrylic Media

Acrylic media is a safe alternative to steel grit and power sand. It's non-toxic, chemical resistant, and reusable. Acrylic media works well for most applications including light etching of metal surfaces, surface finishing on plaster, concrete surfacing, and cleaning of weld joints among others.

Recycled Glass Media

As we mentioned before, recycled glass media is an environmentally friendly alternative to steel shot and other types of sandblasting media. It's safe for the environment, produces less dust collection and fumes and can be recycled time and time again. Commonly used for paint removal, surface preparation on plaster surfaces and metal cleaning among others.

Glass Beads

Glass beads are also used as an abrasive media, and will last longer than sandblasting media due to the reduced wear on the media itself. However, they are heavy, causing the machine to have slightly less mobility.

Walnut Shells

This abrasive blasting media option does minimal damage to the primer layer below or any coating that has been applied to an object.

CHOOSING THE RIGHT BLASTING MEDIA

The key to obtaining the best results is to be aware of how the blasting media varies, as well as when each is appropriate for the jobs you're doing.

IN CONCLUSION

With Dustless Blasting, always remember:

THE MOBILE ADVANTAGE

Dustless Blasting is a low-impact method of blasting that uses water to disrupt the dust plume, making it environmentally friendly and requiring no large confinement. This makes it perfect for blasting things that are too big to go into a blast cabinet or can't be transported. Because they do not generate hazardous waste or require specialized disposal, you may use one of our mobile units safely.

If you're looking for the right abrasive blasting media that is effective, versatile, and will get any tough job done, reach out to us! The right abrasive paired with the Dustless Blasting advantage will make you unstoppable in 2022 and beyond.