At Dustless Blasting we understand surface preparation and the importance of achieving the desired surface outcome when blasting. Whether you are blasting wet or dry, you need to consider the best abrasive for your job to help you improve productivity and lower your cost of operation.

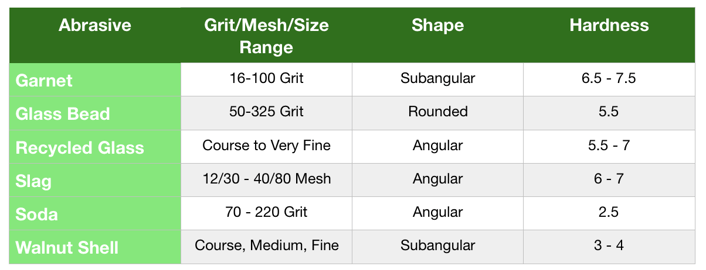

Each abrasive has unique qualities that affect how that abrasive blasts through coating material. The following chart shows just how variant the most popular abrasives are.

Size - Impacts cleaning speed and coverage

Shape - Sharpness of corners and edges effect how deep you get into surface coating

Hardness - The higher the hardness, the more aggressive the abrasive can be

Our favorite abrasive that we like to recommend is recycled bottle glass. We like it because it is clean, inexpensive, safe for the environment and perfect for a wide variety of jobs. Recycled glass and all other abrasives can be purchased from a retailer located in your area.

No matter where you buy your abrasive, always make sure it is a high quality product with consistent particle size and minimal trash. The right abrasive along with adjusting your blast pressure and angles will ensure you can efficiently blast through your job.