Soda Blasting FAQs

Soda Blasting FAQs

What is soda blasting?

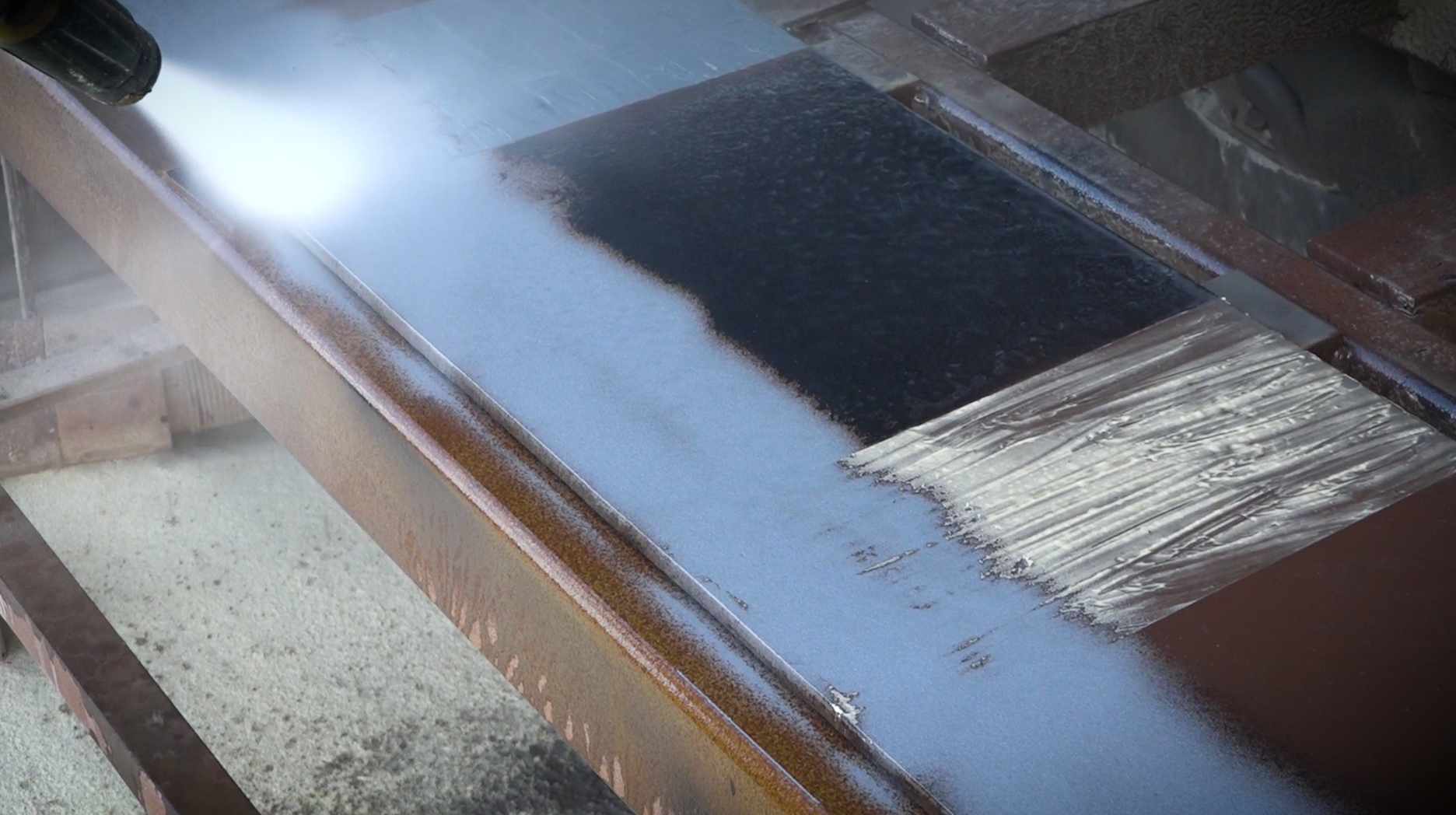

Soda blasting is a method of abrasive blasting that uses sodium bicarbonate, or ‘baking soda’ to strip away any unwanted coatings. During the blasting process, this abrasive and water mixture is forced out the blast pot by compressed air, travels through the blast hose and nozzle, and onto the coating while massively reducing the chance of leaving behind any surface damage . The baking soda will help to clean underneath the coatings as it takes away the unwanted top layers and will leave some of the most delicate substrates unharmed.

CLICK HERE TO LEARN ALL ABOUT SODA BLASTING IN

THE ULTIMATE GUIDE FOR SODA BLASTING: EVERYTHING YOU NEED TO KNOW

Dustless Blasting brings the ability to use a wide array of blast media, and is not limited to soda blasting. Our machines are built to blast using either wet or dry abrasives. We know that no two jobs are just alike. Blasting two cars will most often use the same blast media, but depending on the amount of paint layers, bondo, or rust each car has, there may be a need to adjust the PSI of your blast pot to ensure that each car is blasted optimally. When blasting a customer's car and also the side of their wooden home, two separate kinds of abrasive would most likely be necessary to properly blast each project.

You can find out more about soda as a blast media here.

What equipment is needed to soda blast?

Soda blasting requires a blast pot, a blast hose and nozzle, an abrasive such as baking soda or crushed glass, and water. You will also need a compressor capable of supplying the required CFM based on the size of your blast pot. All of these parts will get the job done quickly and easily, but Dustless Blasting offers many more items to help improve your efficiency at the blast site.

Check out all of our products, including our cooling vests, rust inhibitor, tungsten carbide-lined nozzles, and more at our online store, and learn more about the most efficient ways to put them to work at your next job site here. (Jeff’s post)

What can soda blasting remove?

The answer to almost any question regarding what kind of coating soda blasting is able to remove will be ‘yes.’ Soda blasting is capable of removing paint, rust, chrome, powder coating, and many other other undesirable coatings, while cleaning the surface of your project. Soda is a non-abrasive form of blasting, which means that there is little to no risk of harming the surface you are maintaining.

There are many common uses for soda blasting, among the most practical are fire and smoke damage restoration, paint removal, wood restoration, graffiti removal, marine growth and boat maintenance, car frames and parts, calcium deposits, line stripe removal from streets and curbs, dirt and grime removal, and many more.

Find out more about all of the applications that Dustless Blasting has to offer here.

Is Soda blasting safe?

Soda blasting is among the safest forms of both abrasive blasting and general cleaning solutions. Blasting with baking soda is an environmentally friendly method because baking soda disappears easily and is non-toxic to all humans and animals. Due to the blasting process of mixing the soda with water, there is very little risk that it may leave heat or chemical related marks and damage. The use of baking soda will also help to stop any flash rust. Any sort of toxic material that may be blasted away or be on the surface of the substrate will also be contained by the baking soda and kept from entering the air, potentially harming anything that may be around it.

What is better, soda blasting or sandblasting?

Soda blasting is a generally safer method of abrasive blasting, both for the blaster and for the substrate. Using baking soda as your blast media is a great way to help prevent the spread of rust on your project, while keeping your surface at a low risk of being damaged in any way during blasting. With sodium bicarbonate’s non-toxic nature, it helps your blast area stay safe to be in while making the act of blasting more efficient as it removes unwanted coatings and cleans underneath at the same time.

For more information on the differences of soda and sandblasting, click here.