Make Blasting a Profit Center Inside Your Shop

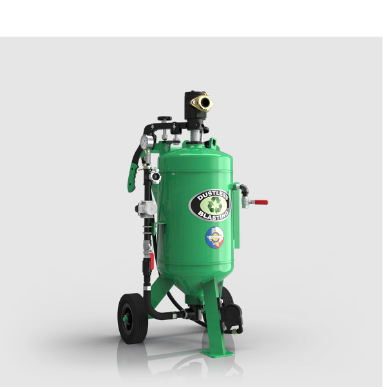

Bring blasting work in‑house with Dustless Blasting® pots so your existing team can handle more jobs, keep quality under your roof, and capture the margin you’re giving away.

Turn outsourced blasting work into a new profit center for your shop.

Increase throughput and quality control by keeping critical work in‑house.

Outsourcing vs. In‑House Blasting

If you’re already sending sandblasting work out the door, you’re paying someone else to do work your shop could keep—and profit from.

| Outsourcing | In-house |

|---|---|

| Higher cost per job, plus vendor markups. | Lower cost per job and the margin stays in your shop. |

| Waiting on someone else’s schedule and delays. | You control timing and can turn jobs faster for your customers. |

| Limited visibility into prep, masking and blasting process. | Full control over prep, blasting, and final finish before it leaves your shop. |

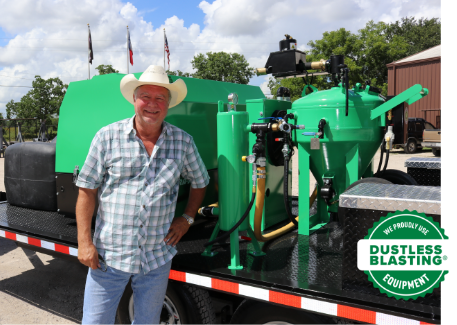

See How a Real Shop Brought Blasting In‑House

Watch an experienced car shop owner explain how Dustless Blasting® fits into his workflow, pricing, and plans to expand.

Add New Services Without Adding New Headcount

Dustless Blasting® pots let your existing team handle more of the work your customers already need.

Automotive: frames, wheels, panels, undercarriages and restoration work.

Industrial & fleet: parts, components, equipment and touch‑ups between paint cycles.

Misc. shop work: powder coat removal, coating prep, rust and corrosion removal.

Easy for Your Team to Learn and Run

You don’t need to hire blasting specialists. We help your existing staff get up to speed quickly.

- Training videos and guides so your team knows how to set up, blast and shut down safely.

- Clear operating procedures to keep blasting integrated into your current workflow.

- Access to parts and support to keep your equipment ready when you need it.

I own one of these systems and I must say it works awesome. I can strip the paint

off a complete car is a few hours and have it ready for primer. So if your planing on restoring your hot rod and need it stripped give me a shout.

FAQS

Common Questions from Shop Owners

Will my staff be able to operate it?

Yes. Dustless Blasting® pots are designed for real shops, not just blasting specialists. With our training resources, most teams get comfortable quickly and can fold blasting into their existing tasks.

What if the equipment sits unused?

If you’re already outsourcing blasting, you likely have enough recurring work to keep the pot busy. Plus, you can add new services—like wheels, frames and small parts—to fill in gaps between bigger jobs.

How long will it take to pay off?

Many shops report paying off their equipment in under a year by moving existing outsourced work in‑house and adding a few new high‑margin services. Your ROI depends on your volume, but we’ll help you run the numbers.

You’re Not On Your Own

- Custom website and online presence tailored to your local market.

- Done‑for‑you Google and social media ads to bring in leads

- Built‑in CRM access so you can track every inquiry, job, and follow‑up in one place.

Contact Us

Tell us a little about your shop and we’ll show you what bringing blasting in‑house could look like for your numbers.