Air Dryers & Aftercoolers for Air Compressors

A cool, clean air supply is proven to increase productivity by 12-15%

Protect Your Tools & Improve Your Results

Water vapor in the atmosphere can condense into liquid during the air compression process. As the air warms, it holds more moisture. That’s why adding an air dryer and aftercooler to your air compressor is essential for maintaining clean, dry, and cool compressed air.

With Dustless Blasting’s Air Drying and Cooling Systems (ADCS), you can protect your equipment and improve your results. High quality and manufactured in the USA—prevent damage to pneumatic tools, avoid clogging during sandblasting, and ensure smooth, flawless painting and coating applications.

Our air dryers are available in a range of formats to meet your needs. From portable units for on-the-go use to heavy-duty systems built for industrial-scale projects. Whatever your application, we’ve got you covered.

When to Use An Air Compressor Dryer & Aftercooling Unit

- Sandblasting (dry blasting): Moisture will make abrasive media or sand clump together in your blast pot and cause clogging. Add an ADCS unit to your air compressor to keep your blast pot free of moisture when dry blasting.

- Automotive painting: Air dryers are crucial for car painting because they remove moisture from the compressed air used to spray paint, ensuring a high-quality finish. Moisture can cause issues like fish eyes, poor adhesion, and hazing, impacting the final look of the paint job.

- Commercial and industrial painting: Moisture in compressed air can cause paint to drip, bubble, or fish-eye, resulting in a poor surface finish. These flaws aren't just cosmetic—they can lead to costly rework, warranty claims, or failed inspections. An air dryer ensures a clean, dry air stream that helps your coatings lay down smooth and defect-free.

- Pneumatic tools and machinery: Improve the performance and lifespan of your pneumatic tools by preventing moisture from corroding and damaging the internal pipes and components of your system.

- Food processing and healthcare: Prevent contamination by keeping your air supply clean and keeping moisture out.

Industries Served

- Oil & Gas

- Shipyard & Marine

- Automotive

- Construction

- Food & Beverage

- Manufacturing & Fabrication

- Surface Prep & Restoration

Explore Our Lineup

Portable ADCS

- Dries air up to 300 SCFM

- Weight: 127 Ib

- Applications: Automotive restoration, construction, shipyards, food & beverage

ADCS-350

- Dries air up to 300 SCFM

- Weight: 273 Ib

- Applications: Body shops, paint booths, manufacturing, heavy equipment

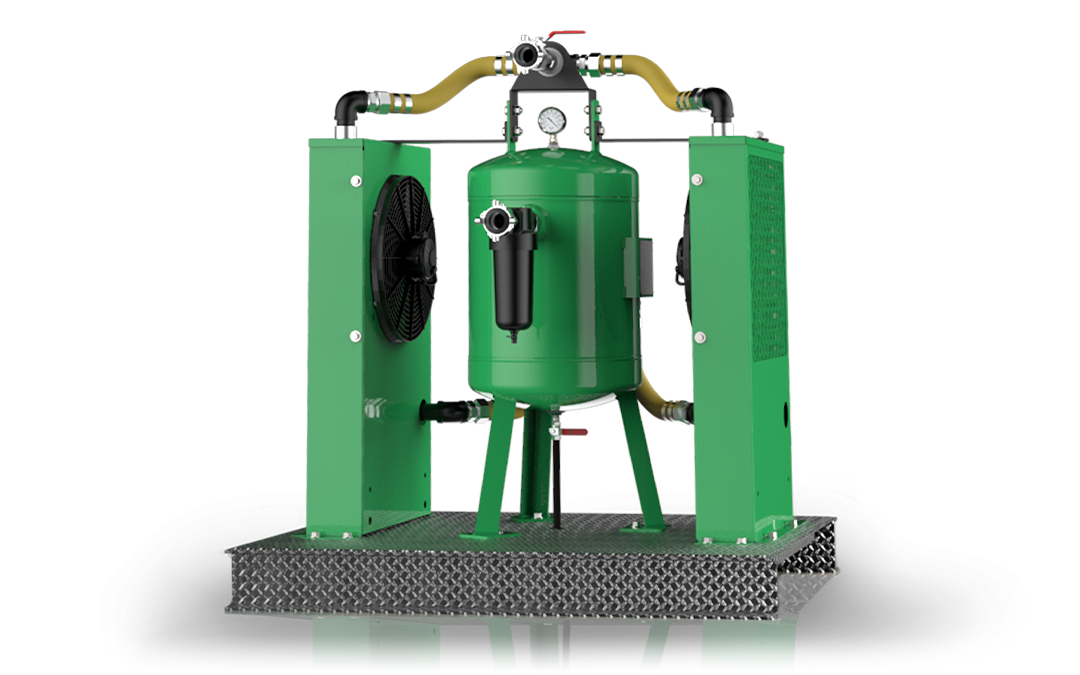

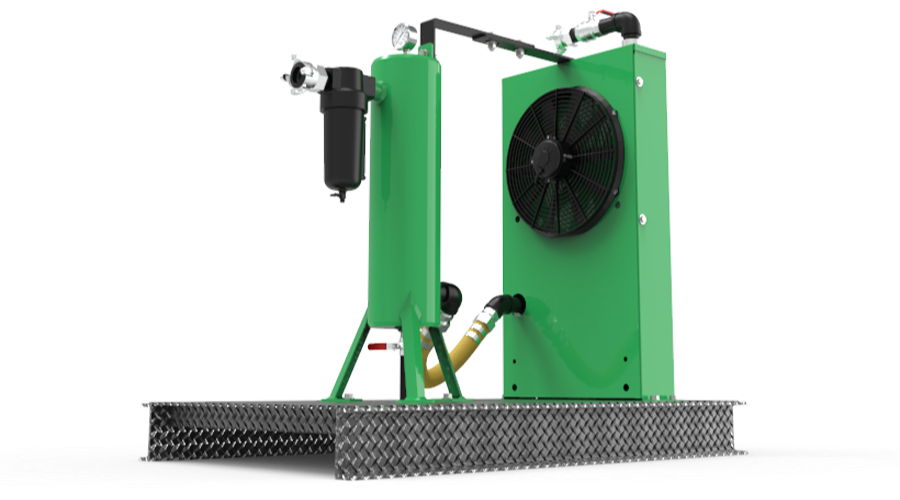

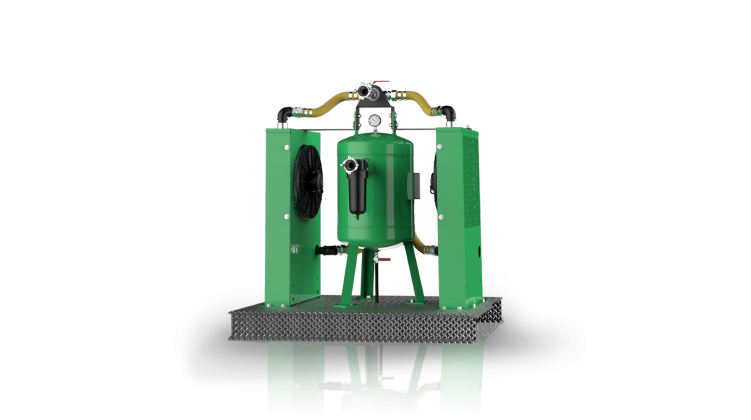

Dual Fan ADCS-2500

- Dries air up to 500 SCFM

- Weight: 446 lb

- Applications: Oil & Gas, shipyard, fleet maintenace, offshore

Benefits of ADCS Units

Prevent flash rust on a blasted surface by eliminating moisture with an air drying and cooling system.

Damp air can damage your machine's filters and essential parts. Prevent unnecessary maintenance with cool, clean, and dry air.

Put money back in your pocket by increasing work efficiency, using less abrasive, and protecting against preventable damage to your blast pot.

The must-have products for surface preparation. Shop spare parts, accessories, blast pots, ADCS, and more!

Shop Other Product Lines

Mobile Trailers

Take your operations on the go! Our sandblasting trailers come equipped with an air compressor, ADCS, blast pot, and water tank to take your business mobile.

Compressor Ready Carts

Looking for mobility in your shop? Our compressor-ready carts are equipped with an ADCS and designed to work with a range of blast pots.

Blast Pots

Own a trailer or working with a fixed setup? Our standalone blast pots are a perfect fit—shop now.

Get Started Today!

Upgrade Your Operations

Learn how you can save your business time and money by bringing all of your surface preparation needs in-house.

Talk To an Expert

Do you need answers before taking the next step? One of our blasting experts would be happy to answer any questions you have about our products.