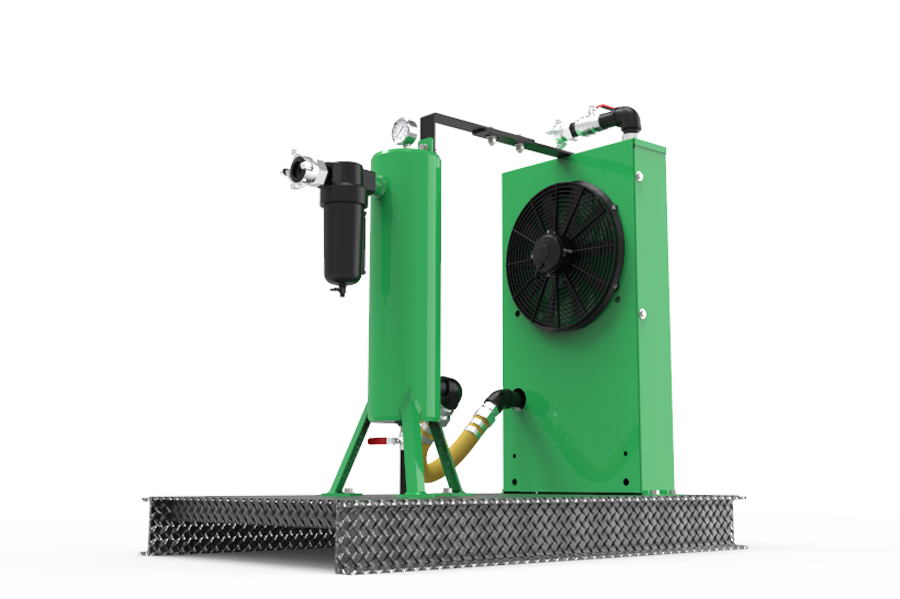

ADCS-350 - Compressed Air Dryer & Aftercooler Kit

Provides a cool, clean, and dry air supply up to 350 CFM

Compressed Air Dryer for Your shop or Paint Booth

Attaching an air dryer and aftercooler kit to your air compressor is essential for maintaining clean, dry, and cool air—key to optimizing your workflow. Proudly made in the USA, Dustless Blasting’s ADCS-350 keeps your pneumatic tools ultra-dry and operating at peak performance by removing moisture from compressed air before it can cause damage.

When air is compressed, its temperature rises, causing water vapor to condense into liquid form. This moisture can damage pneumatic equipment, compromise paint and coating finishes, and lead to clogs that reduce efficiency. The ADCS-350 provides a reliable, stationary solution for drying compressed air in your home, workshop, or paint booth.

Features

Increase Equipment Lifespan

Dry air protects sandblasting machines, paint guns, and pneumatic tools from internal rust and corrosion caused by trapped moisture

Decrease Operating Costs

Reduces downtime caused by clogged lines, wet abrasive media, or tool malfunctions—keeping your projects on schedule and your customers satisfied

Removes Moisture at the Source

Cools hot compressed air (up to 300CFM) and extracts moisture before it ever enters your lines—eliminating water contamination in your media, coatings, or tools.

Specifications

- Dimensions: 48" L x 31" W x 48" H

- Weight: 273 lb

- Fan Power Consumption: 12V and 6 amps/hour

- 350 CFM Capable Water Trap

- Moisture Separator

- 1 1/4” Air Inlet and Discharge

- 0–300 PSI Gauge

- 1 1/4” Shutoff Valve

- 1/4” Moisture Drain

- 10’ Battery Cables

When to Use ADCS-350

- Workshop or Paint Booth Use: This stationary kit is perfect for sandblasting or painting operations out of your workshop. Prevent clumping during abrasive media blasting and eliminate paint texture issues.

- Pneumatic Tools or Air Instruments: Protect your equipment from moisture damage and corrosion.

- Vehicle Restoration: Eliminate fisheyes or blisters from paint application in vehicle or fleet restoration.

- Heavy Equipment & Commercial Cleaning: Remove rust, mold, and other tough surface contaminants for commercial and health applications.

Industries Served

- Automotive & Body Shops

- Surface Prep & Restoration

- Manufacturing & Fabrication

Benefits of ADCS Units

Prevent flash rust on a blasted surface by eliminating moisture with an air drying and cooling system.

Damp air can damage your machine's filters and essential parts. Prevent unnecessary maintenance with cool, clean, and dry air.

Put money back in your pocket by increasing work efficiency, using less abrasive, and protecting against preventable damage to your blast pot.

The coolest way to maximize your blast

Combine your power

Rather see our products in person? We're happy to offer hands-on demos in Houston, TX.

Shop Other Products

Portable ADCS

Need an air drying and cooling solution on the go? Our portable ADCS can pair with a DB150-500 blast pot to take your operation mobile!

Compressor Ready Carts

Looking for mobility in your shop? Our compressor-ready carts are equipped with an ADCS and designed to work with a range of blast pots.

Mobile Trailers

Mobile trailers offer a complete setup including an air compressor, water tank, ADCS unit, and blast pot, all mounted on a towable trailer.

Get Started Today!

Talk To an Expert

Do you need answers before taking the next step? One of our blasting experts would be happy to answer any questions you have about our products.

Upgrade Your Operations

Learn how you can save your business time and money by bringing all of your surface preparation needs in-house.