Car Restoration - A Complete Guide

Car restoration is a labor of love and dedication. It can be an incredibly rewarding process, with the right attitude and know-how. To ensure you get the most out of your classic car restoration project, it’s important to understand what goes into it. This guide will provide an overview of car restoration basics, including how to safely remove paint, rust, and bondo without damaging the vehicle. With this information in hand, car enthusiasts can feel confident that they are well-equipped to complete car restoration jobs of any size. Get ready to restore your classic car with confidence!

The Best Methods for Classic Car Restoration

There are many products available to choose between for classic car restoration. However, having more options doesn't always make the decision easier. In fact, some methods are not only outdated, but pose risks to the user and car surface itself. The quality of service you provide and the success of your project will largely depend on using top notch surface restoration methods. Let's take a look at what most automotive professionals are using to make improvements to their shop.

The easiest, safest and most effective way to restore a car is by using an abrasive blasting system that can remove paint, rust and body filler in one step. This involves using a blast media such as crushed glass in conjunction with pressurized air or water to propel the media against a surface. This process will easily remove unwanted coatings and create an anchor profile for new paint to adhere to.

You'll want to use a machine that is capable of adjusting pressure settings and that can easily switch between wet and dry blasting. This allows the operator to really customize the blasting method for each job, because no coating, surface or job is the same! Dustless Blasting has become wildly known and recommended in the automotive industry for being versatile enough to safely restore cars without damaging them. This is because our system can use water to wet blast body panels without warping and can easily switch to dry blasting interior spaces where you'll want to blow out dry media from the nooks and crannies.

In order to really understand the best method for these types of projects, it's important to compare different restoration options. Below are a list of commonly used methods for car restoration that may cause more harm than good to your classic car.

Outdated Methods For Automotive Restoration

Many traditional methods for car restoration projects are now seen as outdated and potentially harmful to both the operator and classic car. Below is a list of commonly used methods that you should think twice about before using.

Sanders and Grinders:

Using a grinder or sander to remove car paint is not an ideal option for car restoration due to production rates. These hand-held tools take significantly longer to remove coatings on any surface compared to an abrasive blasting system. If you own a blasting business or auto body shop, you know that time is money. So you have to ask yourself how much time you're willing to waste on these types of tools. An abrasive blasting system can have a car completely restored in a couple of hours, whereas a sander or grinder could take days.

Additionally, you may find that there are some tight spots on your car that hand sanders simply can't get to.

Sandblasting

While dry abrasive blasting interior spaces is a good option when working on an automotive project, that is not the case for body panels. Sandblasting body panels can be incredibly harmful to car surfaces and will often warp the surface leaving behind carvings and depressions, as well as a surface that is difficult to repair. If you're using sand as an abrasive, it is crucial you know the health hazards associated with inhaling those airborne particles. Inhaling silica sand can cause severe health issues like lung cancer. Because of this, we recommend never using sand as your choice of media. 40/70 crushed glass is a great abrasive choice because it is chemically inert, environmentally friendly and contain less than 1% free silica.

Using Chemicals

Chemical dipping was once an option for car restoration, but has since been deemed dangerous and time consuming. EPA and safety regulations have banned Methylene Chloride from being used in most chemical strippers because of its harmful side effects to workers. After removing the harmful Methylene Chloride from products, chemical stripping takes much longer to eat into the paint than abrasive blasting. It's also important to know that most strippers on the marketing can ruin fiberglass cars by damaging the gel coat and the epoxy resin that creates the fiberglass structure.

Beyond the obvious health risks, chemical stripping does not leave an anchor profile for paint to adhere to the surface. So you'll want to consider the time it will take to scrape off the affected coating, clean the body to remove the remaining chemicals, and then sand the surface to achieve an anchor profile.

Learn more about why Dustless Blasting is the best method for car restoration compared to other methods in this blog article.

How To Restore Cars With Dustless Blasting

Now that you know the preferred method for car restoration, it’s time to dive into the specifics of how to effectively restore a car and get the best results. There are many steps that go into restoring a vehicle with an abrasive blasting system. Below is a list of prep, safety and blasting tips you should consider when using a Dustless Blaster on a car.

Before the job

In order to quote the job correctly and perform high quality work, it's important to develop a plan and understand the customer's expectations. What finish does it he want to achieve? Will you be responsible for prep and clean up? If you reveal bondo, does he want to leave it intact or have it removed? All of these questions help to leave a satisfied customer.

Vehicle Prep

Before blasting any car, you’ll want to mask off all rubber, chrome, plastic, glass, and electrical wires, as any form of abrasive blasting may damage them. What can’t be completely removed should be covered. You'll also want to set up your blast area. To contain and dispose of waste properly, cover your blast area in plastic so you can roll it up and dispose of it after the job.

Choosing The Right Abrasive

Choosing the right abrasive is one of the most important steps for any blasting job. Different abrasives work best on specific surfaces, so you need to find an abrasive that match both your production needs and surface requirements. Dustless Blasting machines allow you to use a wide variety of abrasives, whether you're blasting wet or dry. For wet blasting, you can use any abrasive that is clean, consistent, sinks in water and is not water soluble. 40/70 crushed glass is the preferred choice for car restoration because it can easily remove paint and rust without damaging the car’s underlying metal. Learn more about choosing the right abrasive and abrasives to avoid for automotive restoration in this article.

Blasting Techniques For Cars

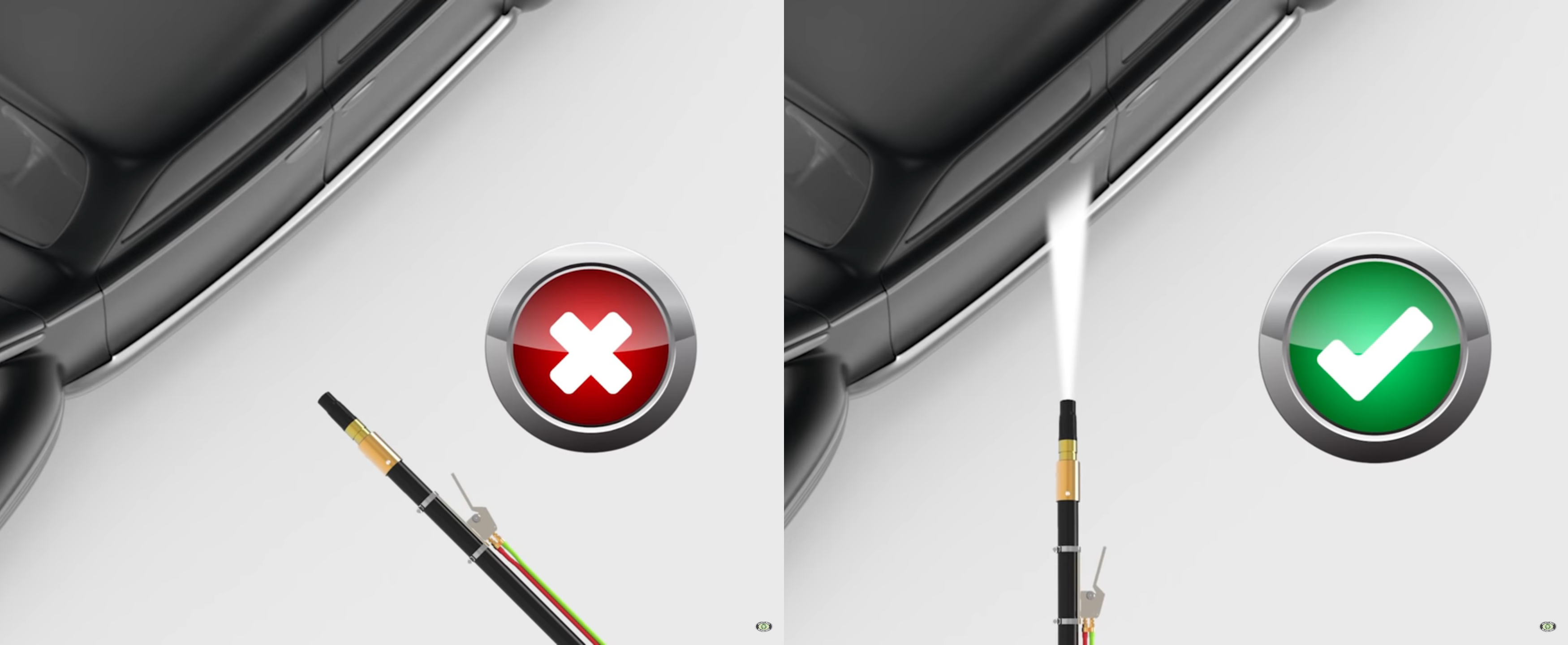

The most important tip when blasting any car is to hit the surface at a 30 degree angle rather than straight on. This technique helps to peel the paint off instead of pounding it in. You'll also need to maintain an appropriate standoff distance. When close to the surface, you'll see faster removal but from a smaller area which will lead to unnecessary fatigue. Backing off increases the blast pattern size and allows a more comfortable pace, while evenly distributing the pressure on your panels.

What makes Dustless Blasting a top choice for automotive restoration is that the operator can easily switch from dry blasting to wet blasting. Wet blasting reduces the temperature of the blast surface, which eliminates heat related warping of thin body panels. Keep in mind that metal can still bend under too much pressure, or stretch when friction is applied too heavily to a small area. If you’re blasting thin or large panels like hoods or trunk lids, you’ll want to blast from farther away than you normally would, spreading out the blast pattern more.

Preventing Rust

Get ahead of protecting your work with a quality rust inhibitor. The blasting process, wet or dry, can create rust. Properly washing away contaminants will help extend the life of any coating on a truck or classic car you're working on. The Dustless Blasting Rust Inhibitor prevents flash rust for up to 72 hours, giving you time to prime the vehicle once blasting is complete. This product is non-hazardous and leaves the surface primer-ready. Learn more about how it works and how to use it on automotive projects in this article.

An Equipment Guide For Classic Car Restoration

We've already established that an abrasive blasting system is the most appropriate tool to use for automotive restoration jobs, but let's take a look at how Dustless Blasting equipment offers certain solutions to various parts of these projects.

Our pressurized blast pot effectively removes all kinds of coatings without damaging the surface underneath - improving the surface restoration industry at large. Below is a list of what Dustless Blasting equipment offers workers and shop owners:

-

Blast pots can blast both wet and dry.

-

Wet blasting reduces dust - improving worker safety (Wet abrasive blasting is OSHA recommended).

-

Dustless Blasters use a venturi suction method which prevents clogging.

-

This system is able to use a variety of abrasive materials for better results.

-

Mobile units come with an Air Drying and Cooling System which removes moisture from compressed air by cooling it down.

To learn more about why surface preparation experts choose Dustless Blasting equipment and accessories, checkout this article.

Start Restoring Cars With Dustless Blasting

With so many business owners using Dustless Blasting equipment to restore cars, we recommend checking out some automotive case studies if you're still hesitant about what this tool can do for your next restoration project. These real jobs will hopefully give you the confidence to start using an abrasive blasting system to efficiently and safely transform any vehicle.

Now that you have a better understanding of car restoration do's and don'ts, it’s time to get started. If you're still using the outdated methods we discussed earlier, it's time to consider purchasing a Dustless Blasting machine for all your automotive restoration projects. We're here to help if you have any questions about car restoration or need help selecting the right equipment for your project. Contact us today and let's start restoring cars! Don't forget to check out our Online Store for all your must-have blasting tools, consumables, parts and accessories.