Construction Surface Preparation: Powerful Equipment for Professionals

In the construction industry, surface preparation isn’t just a step—it’s the foundation of a successful project. Whether you’re preparing concrete for a fresh coating, restoring the natural beauty of brick or stone, or creating a surface profile after structural repairs, Dustless Blasting® equipment is your go-to solution.

Proper surface preparation is important for achieving a durable finish and ensuring coatings last longer, as it helps prevent premature wear and extends the lifespan of your work.

We serve general contractors, masonry professionals, and specialty restoration crews who demand efficiency, quality, and durable equipment for longer-lasting results on every job site.

Construction Surface Preparation Done Right

Surface preparation often requires that surfaces are thoroughly cleaned before removing coatings, grime, efflorescence, paint, or sealers from a wide variety of substrates. Loose or damaged material must be removed from the substrate to ensure proper adhesion. Preparing the substrate by removing loose debris is essential for optimal results. Our blasting systems are designed to handle it all—wet or dry—while keeping dust to a minimum and productivity high.

Common Applications:

- Sandblasting concrete surfaces to remove paint, sealants, or grime from walkways, floors, driveways, parking garages, overpasses, etc., and to prepare the surface to apply new coatings or sealants.

-

Stone restoration for historical buildings, hardscapes, monuments, and public spaces, including applying specialized finishes or treatments as part of the restoration process.

-

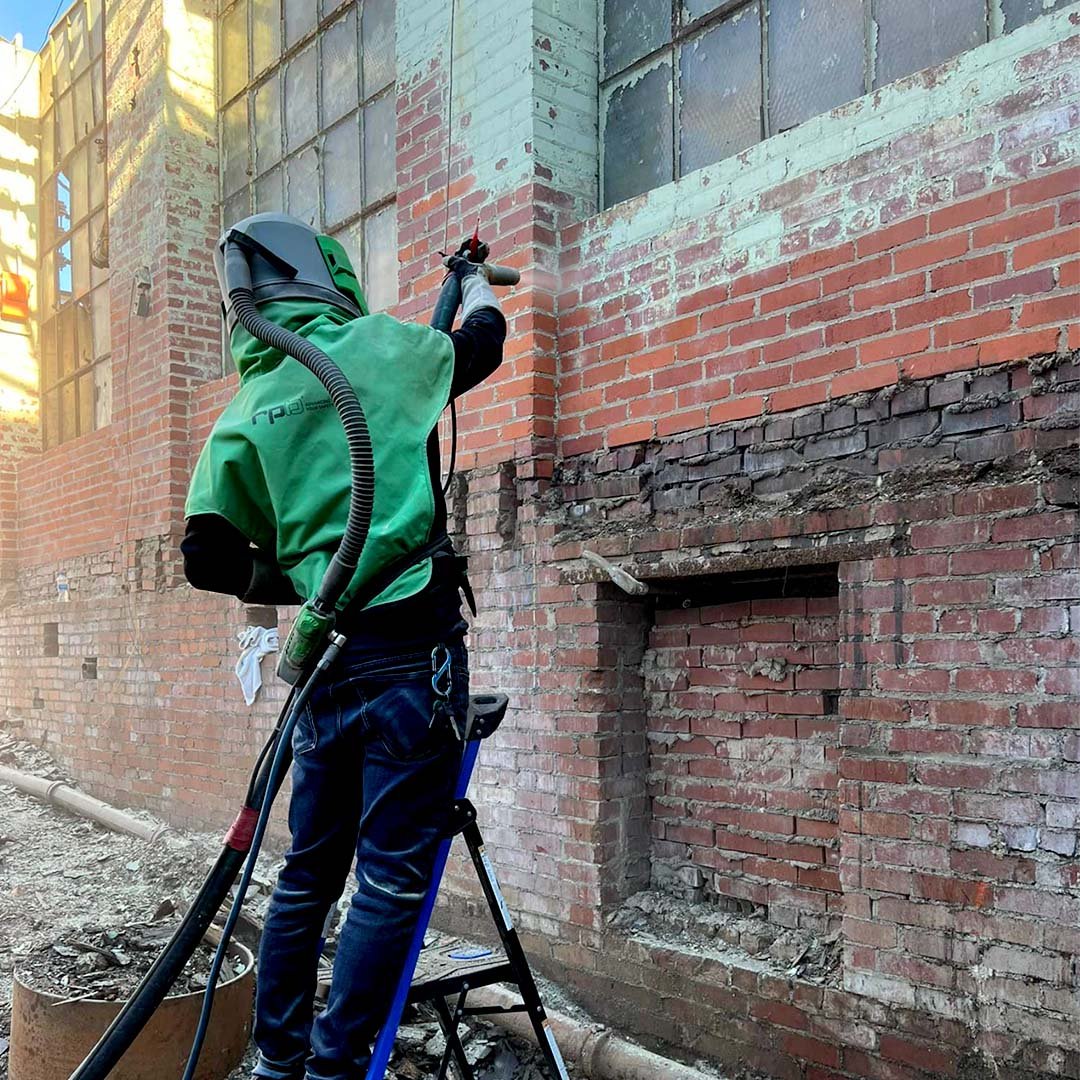

Brick restoration on homes, chimneys, and commercial buildings.

-

Steel and metal restoration for removing surface contaminants before painting or coating.

-

Graffiti removal from masonry and concrete.

Whether you’re working on new construction, renovations, or historic restorations, our equipment gives you the flexibility to adapt to every job.

Brick Restoration

Old, stained, or painted brick can be tough to restore without causing damage. Traditional methods may be too aggressive, risking etching or deterioration of the surface. Dustless Blasting gives you total control over pressure and abrasive flow, so you can gently clean and restore brick while preserving the original texture. Protecting and sealing brick joints with appropriate fillers is essential to prevent chipping and maintain the structural integrity of the masonry.

Whether you’re removing paint from a fireplace, soot from a chimney, or decades of grime from an old property, our system is ideal for sensitive brick restoration jobs.

Blasting brick safely is critical due to the presence of silica in masonry materials. When brick is dry blasted, it can release respirable crystalline silica dust—an airborne health hazard that can lead to serious conditions like silicosis if inhaled. Dustless Blasting helps mitigate this risk by using water to suppress dust at the source, making it a safer alternative for both operators and nearby workers.

Wood Restoration

From historical buildings to modern decks and beams, wood surfaces require a gentle touch during restoration. Dustless Blasting offers a controlled approach—removing paint, stain, mildew, or grime without damaging the wood grain.

Whether you're restoring a log home, refinishing wooden siding, or prepping beams for sealing, Dustless Blasting provides the flexibility you need. You can lower the pressure and use a fine abrasive like crushed glass or soda to gently clean the surface without harming the structural integrity of the wood.

Sandblasting Concrete

Removing paint, sealers, coatings, or grime from concrete requires power—but also precision. With Dustless Blasting, you can clean or profile concrete surfaces quickly and efficiently while drastically reducing airborne dust.

Our equipment is widely used for sandblasting concrete driveways, patios, parking garages, warehouse floors, and more. Dustless Blasting delivers a clean, etched surface that’s ready for paint, epoxy, or sealant—without the mess of dry blasting or grinding.

Stone Restoration

From limestone and granite to marble and sandstone, natural stone is both beautiful and delicate. That’s why stone restoration work demands equipment that can clean thoroughly without causing micro-cracks or surface erosion.

Dustless Blasting helps create the ideal surface profile, bringing stone surfaces back to their original beauty. It allows you to restore headstones, monuments, retaining walls, and architectural stonework with the perfect balance of power and care.

Construction Equipment Restoration

Job sites are tough on equipment. Over time, construction machinery like excavators, skid steers, trailers, and cranes can accumulate rust, grease, paint overspray, and grime that not only affects their appearance but can also impact performance and resale value. Dustless Blasting makes it easy to bring these machines back to life.

Our equipment is powerful enough to remove tough coatings like epoxy, industrial paint, concrete, and corrosion from metal surfaces. Whether you're refreshing your fleet or prepping machinery for resale, Dustless Blasting delivers fast, thorough cleaning without the need for harsh chemicals or extensive manual labor.

Industry Challenges & How We Help

Challenge: Delicate Surfaces at Risk of Damage

Solution: Our adjustable pressure and abrasive flow make it easy to clean sensitive materials like wood, stone and brick without etching or harming the surface. Use a fine abrasive or soda for gentler restoration work.

Challenge: Dust, Debris & Clean-Up Concerns

Solution: Choosing to wet blast with Dustless Blasting® combines water and abrasive to trap airborne particles, significantly reducing dust by 97% compared to traditional sandblasting. Ideal for restoring brick and concrete as these surfaces will release crystalline silica dust when dry blasting. Wet blasting is also a great process for urban job sites, indoor projects, and areas with tight environmental regulations.

Challenge: Inconsistent Coating Adhesion

Solution: Improper surface prep leads to coating failures and costly rework. Our equipment creates the ideal anchor profile for coatings, sealers, and paints—ensuring they are properly applied for optimal adhesion and long lifespan.

Challenge: Labor Costs & Time Constraints

Solution: Our mobile-ready and compressor-powered units are fast, easy to set up, and built for serious productivity. Spend less time prepping and more time building.

The Right Equipment For The Job

We offer a full line of mobile and stationary systems suited for construction applications of all sizes.

Proper surface preparation is essential to ensure a successful installation of flooring or wall systems, as it provides a clean and structurally sound substrate for optimal performance.

Compressor-Ready Carts

Great for contractors who already own an air compressor and who want wet and dry blasting capabilities. Compact, affordable, and powerful.

These systems feature:

-

Blast pot: ready for wet or dry blasting applications

-

Air dryer and cooler: critical for preventing clogs when dry blasting

Mobile Blasting Trailers

For teams that need a fully self-contained with it's own air source. Every mobile unit includes:

-

Onboard air compressor

-

Blast pot for wet or dry blasting

-

Built-in air cooler and dryer, allowing for dry blasting and media use with zero moisture issues

-

Trailer-mounted, ready-to-go system, no setup required