About Soda Blast Media

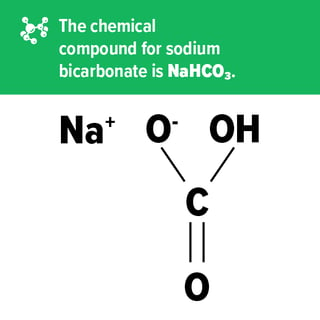

Soda blasting is an incredible way to remove paint, grease, and other applications from a variety of objects with just water! The media used in this process, sodium bicarbonate or “baking soda” as it's also known - not only does the abrasive action help break down surfaces but you don't even need any other chemicals because these ingredients are all found naturally within your home.

Soda blasting uses compressed air to shoot a stream of sodium bicarbonate through a nozzle at high speed. The forceful impact of the baking soda against the surface effectively removes any build-up or grime. Unlike other types of abrasive media, sodium bicarbonate is a single-pass media. It cannot be recycled for additional use. Sodium bicarbonate or baking soda is generally considered to be a safe and environmentally friendly alternative to traditional methods of cleaning, such as sandblasting.

What kind of nozzle do I need to blast with Soda?

The nozzles you choose can make or break your day. Nozzle size and type determine the volume of air needed and the size of the air compressor required to achieve the desired blast pressure. An inadequate air supply can greatly reduce performance, production rates and cost efficiencies

Check out our nozzle selection here!

Does soda blasting cause a lot of dust?

ARMEX is a commonly used soda blasting media that can be used wet or dry. When wet with water it becomes even more effective at containment and scrubbing sidewalks clean! However, when using soda dry be sure to take precautions since without some form of mitigation measures, such as negative air chambers etc., your workplace could potentially become filled with dust instead.

When you are working with sodium bicarbonate, it is important to use the proper protective equipment. This can include outerwear and a face shield or dust filtration mask while also wearing safety glasses earplugs as well gloves that protect from cut fingers!

Our Nova Kit is a great system for the ultimate protection when blasting.

Cost of Soda Blasting

Soda blasting is more expensive than traditional sandblasting. The higher cost for soda comes from the media, machinery and labor needed to create it as well as its subsequent recycling costs when compared with other types of abrasive media like glass beads or steel shot that have a stronger molecular structure making them less fragile over time if properly maintained.

So you want to try soda blasting?

Well, that’s great! It can be a very effective way of removing rust or scaling from metal surfaces. Before you begin, make sure all of your blast media is in order, and that the type of nozzle that will work best with your machine has been determined.

CLICK HERE TO LEARN ALL ABOUT SODA BLASTING IN

THE ULTIMATE GUIDE FOR SODA BLASTING: EVERYTHING YOU NEED TO KNOW