10 Reasons Dustless Blasting is the Future of Surface Preparation

Dustless Blasting is a revolutionary paint stripping and cleaning system that can remove virtually any coating from any surface.

Paint eventually fails, metal eventually rusts, and surfaces get dirty. Dustless Blasting lets you remove what is left of the old coatings quickly and efficiently, leaving a smooth, clean surface that is ready to be made new again. Demand for this service is everywhere, which creates endless opportunities for new businesses to start and existing businesses to expand.

Blast Faster - Coatings can be stripped in record time, leaving a clean, paint ready surface all in one step.

Blast Better - Wet blasting creates less mess and allows for easy containment. Plus, it's an eco-friendly method that complies with government regulations!

Blast More Efficiently - Dustless Blasters are designed to combine water and abrasive so that you can clean and strip your surfaces while consuming less media per job.

Below are 10 reasons that show how Dustless Blasting is the quickest, most efficient and environmentally friendly form of paint stripping and cleaning available.

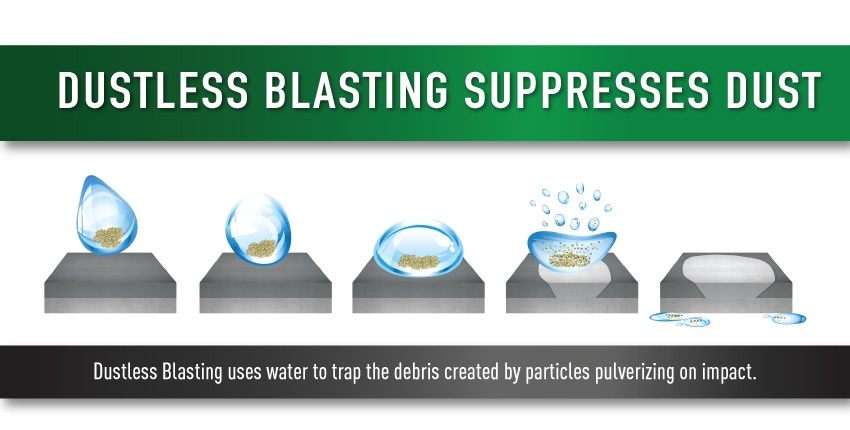

Dust Suppression

Dust Suppression

Water and abrasive are mixed inside the blast tank. During blasting, the water encapsulates the abrasive and the coating being removed. Instead of becoming airborne, the trapped abrasive falls to the ground, keeping surrounding areas clean and free from mess.

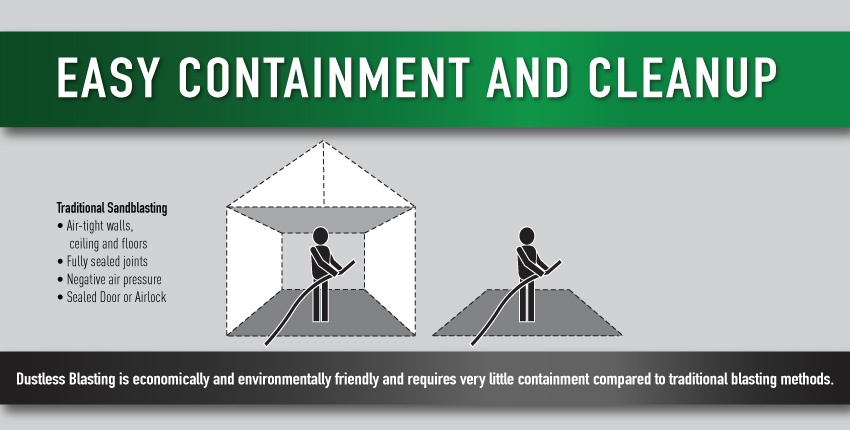

Easy Containment

Because water is mixed with the abrasive, there is no dust plume or ignitable sparks. This allows you to blast in open environments, even when others are working nearby. Plus, you will save money on containment and cleanup costs.

Safe & Efficient

Unlike traditional sandblasting, Dustless Blasting produces no toxic dust plume. That means you don't need to wear a full blast suit. This increases your visibility and your ability to maneuver, which in turn reduces the risk of accidents.

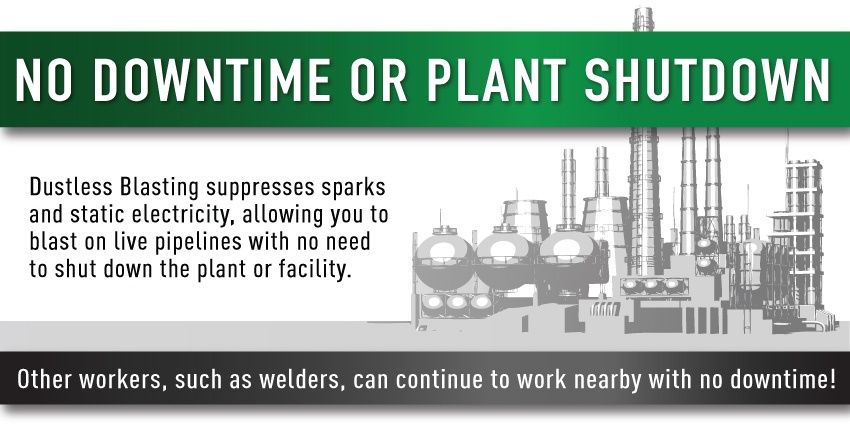

No Plant Shutdown

Dustless Blasting is environmentally friendly, easy to contain and clean, and produces no ignitable sparks. This makes it the perfect tool for working on live pipelines and offshore rigs as workers can continue to work nearby.

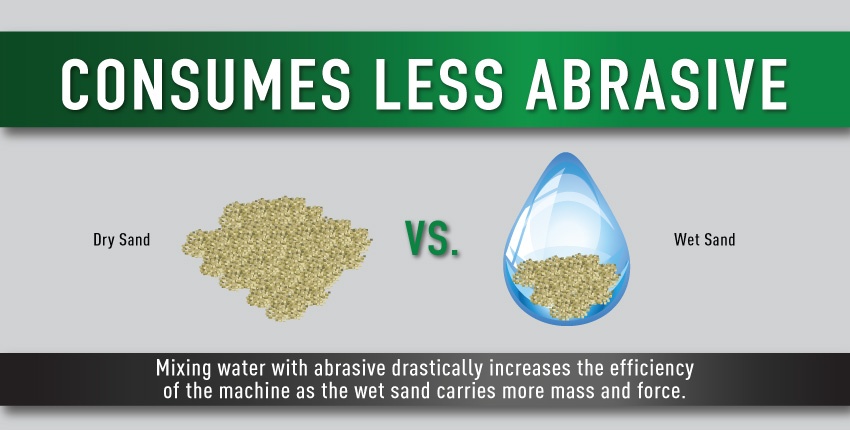

Consumes Less Abrasive

The combination of water and abrasive produces more mass and force in the blasting process, allowing you to use less media and work more efficiently. This not only speeds up your production time but also cuts your consumables cost.

Cleans Surfaces

Dustless Blasting not only strips away old paint and rust, but actually cleans the surface that you are blasting so that it is free of contaminates and soluble salts that cause flash rust. In addition to this, Rust Inhibitor can leave a freshly stripped surface paint ready for up to 72 hours. This makes it the perfect method of paint stripping for the automotive restoration business.

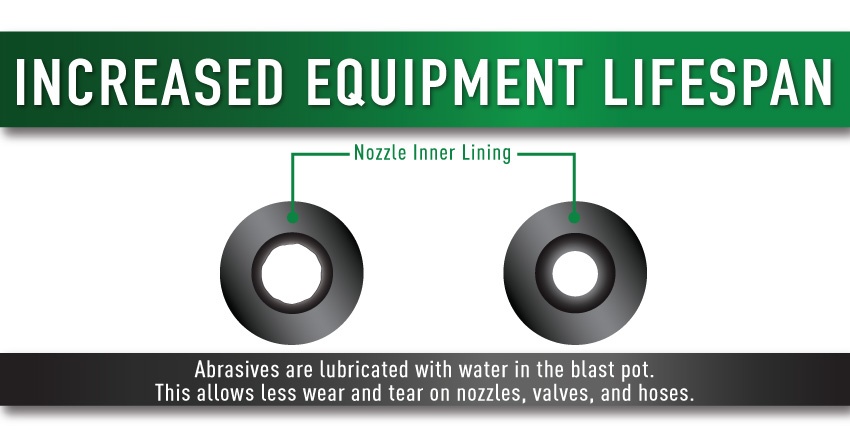

Increased Equipment Lifespan

Water lubricates the abrasive as it moved through the pot, hose, and nozzles. This reduces the amount of heat transfer and wear and tear on your equipment so you can keep on working one job to the next.

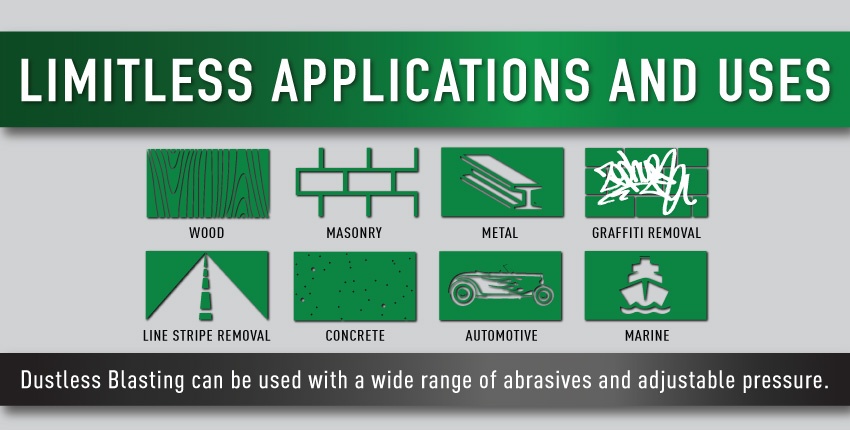

Limitless Applications

Dustless Blasting has such a wide variety of applications and uses. The process can be used on nearly any type of surface such as wood, brick, metal, concrete, and more. This process can be used in any and all industries: automotive, marine, industrial, residential, refinery, and so much more.

Environmentally Friendly

Environmentally Friendly

Since the debris is captured with the water during the blasting process, Dustless Blasting can be easily contained and cleaned. Because there is no dust plume or toxic chemicals, it's perfect for use in areas with strict environmental rules and regulations. Learn more about this environmentally friendly process.

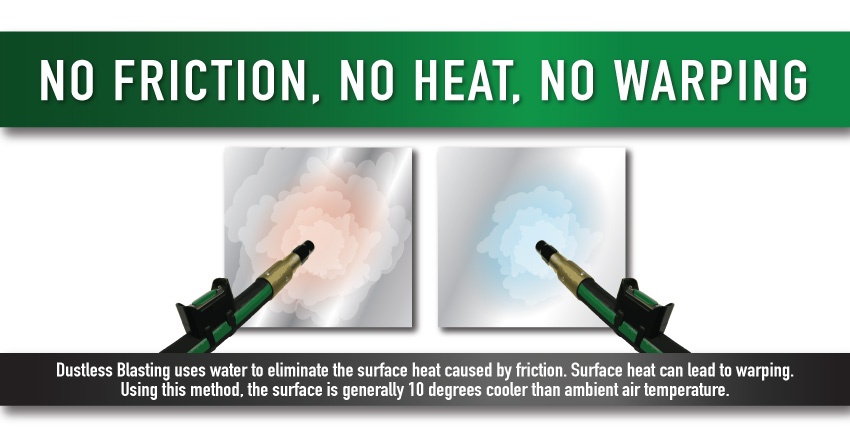

No Friction, No Heat, No Warping

Dustless Blasting is perfect for blasting all metals with no fear of friction, heat, or warping of the surfaces. The water used in the blasting process helps to keep the surface about 10 degrees cooler than the ambient air temperature. This helps to eliminate the surface heat generated by friction. No surface heat means NO WARPING.

If you have questions about the numerous uses of the Dustless Blaster, feel free to contact us at team@dustlessblasting.com or 713-869-2227.

Don't forget to download the entire infographic here!